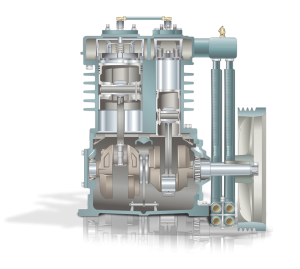

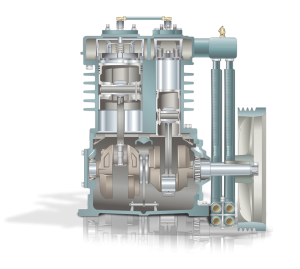

M L Series Air Compressor

L Series Air Compressor

Safety Precautions The owner, lessor or operator of any compressor unit manufactured by FS Curtis, Inc. is hereby warned that failure to observe all safety precautions may result in serious injury of personnel and/or damage to property. FS Curtis, Inc. neither states as fact, nor in any way implies that this list of safety precautions is an all-inclusive list, the observance of which will prevent all damage to property or injury to personnel. Every reasonable effort has been taken to ensure that complete and correct instructions have been included in this manual. However, possible updates and changes may have occurred since this printing. FS Curtis,Inc. reserves the right to change specifications, without incurring any obligation for equipment previously or subsequently sold. Compressors and/or units are assembled to comply with the customer’s purchase order and in compliance with FS Curtis, Inc. specifications; alteration must not be made to the compressor or unit without FS Curtis’ written approval.

DANGER! Air used for breathing or food processing must meet O.S.H.A 29 C.F.R. 1910.134 or F.D.A. 21 C.F.R. 178.350 regulations. Failure to do so will cause severe injury or death.

WARNING! Compressors are precision high-speed mechanical equipment requiring caution in operation to minimize hazard to property and personnel. Listed below are some safety precautions that must be observed. Use of Curtis Compressors to transfer toxic, radioactive, flammable, or explosive substances is prohibited. Do not install the compressor in an area where there is a risk of exposure to explosive gases or combustible dusts, such as flours, starches, coke, coal dust, etc. or in close proximity to corrosive substances. Release all air pressure from the system before working on the unit and red tag all electrical control switches. On base mounted units with no receiver tank, the installation of safety valves in the discharge line is the responsibility of the end user. Failure to install safety valves in the discharge line could cause property damage, injury and / or loss of life. Do not operate compressor on a shipping skid or any other unapproved mounting surfaces. Do not by-pass motor over-current protection. Do not change the setting or in any way affect the operation of the safety valves. Turn off and lockout/tagout the main power disconnect switch before attempting to work or perform any maintenance. Do not attempt to service any part of this unit while it is running. Ensure that service personnel are properly grounded before attempting to service any part of the electrical system. Do not operate the unit with any of its safety guards, shields or screens removed. Do not remove or paint over any DANGER!, WARNING!, CAUTION!, or instructional materials attached to the compressor.

Lack of information regarding hazardous conditions can cause property damage or personal injury. Do not change the pressure setting of the pressure relief valve, restrict the function of the pressure relief valve, or replace the pressure relief valve with a plug. Do not install a shutoff valve in the compressor discharge line without first installing a pressure relief valve of proper size and design between the shutoff valve and the compressor.

Do not use plastic pipe, unapproved rubber hose, or lead-tin soldered joints in any part of the compressed air system. Alterations must not be made to this compressor without FS Curtis’ expressed, written approval.

Do not operate the compressor in excess of the A.S.M.E. pressure vessel rating for the receiver or the service rating of the compressor, whichever is lower. Surface temperatures can exceed 400 °F, power off the unit and allow it to cool before touching any surface of the compressor.

Provisions should be made to have the instruction manual readily available to the operator and maintenance personnel. If for any reason any part of the manual becomes illegible or the manual is lost, contact your local distributor. Your State and/or local OSHA regulations may require a Pressure Vessel Permit to operate this equipment. Obtaining a permit is the sole responsibility of the owner, lessor or operator of the equipment. Contact your State/Local OSHA for more information.

FS Curtis manufactures a broad array of compressor configurations to satisfy the needs of our diverse customer base. Despite this diversity, all FS Curtis two stage compressor configurations work off the same basic cycle.

Air is drawn into the compressor through the air intake and filter assembly. The air enters the first stage, a low pressure chamber where it is compressed the first time. As air is compressed, its temperature increases, this hot air then enters the intercooler where the temperature is reduced.

Next, the cooled air enters the second stage, a high pressure chamber where the air is compressed a second time to even higher pressures and discharged into the tank.

An Ultra Pack option can be purchased with an installed air-cooled after-cooler which, after the second compression stage, cools the air to a 20°F approach temperature before being stored in the tank. When the compressor has filled the tank to its pressure rating, the pressure switch disengages which turns off the motor, preventing the tank from over pressurizing. Finally, the tank has a ball valve which is opened or closed by the operator and lets air out of the tank.

Duplex units operate in much the same way as simplex units, only there are two compressors. The key difference is in the pressure switch and starter. In a duplex unit, there are two pressure switches, a “lead” pressure switch and a “lag” pressure switch set 10 psi lower than the lead switch. The alternator utilizes both compressors to fill the tank. Once the tank approaches the cutoff “lag” pressure, the alternator selects one compressor to be the “lag” compressor and cycles it off, using only the “lead” compressor to provide the remaining pressure. The alternator then cycles between both compressors, switching the “lead” and “lag” compressor and ensuring roughly equal wear between them. If air usage exceeds the output of a single compressor, the alternator utilizes both the “lead” and the “lag compressor to fulfill operating conditions, once again cycling off the “lag” compressor when its cutoff pressure is reached. Base mounted Large Industrial compressors are capable of outing large amounts of air at high pressures and come in single stage, two stage, or high pressure varieties. They work off the same basic compressor cycle that tank mounted units operate on.

NOTE: As these units do not come with a receiver tank, the installation of safety valves in the discharge line is the responsibility of the end user.

INSTALLATION IMPORTANT NOTICE Abide by all applicable state, local and regulations when mounting and installing the compressor. Failure to do so may result in injury or death and will void the manufacturer’s warranty. Contact your local government for more information.

CAUTION! Improper lifting can result in component or system damage or personal injury. Follow good shop practices and safety procedures when moving the unit.

Receiving

Immediately upon receipt of compressor equipment and prior to completely uncrating, the following steps should be taken: 1. Inspect compressor equipment for damage that may have occurred during shipment. If any damage is found, demand an inspection from the carrier. Ask the carrier how to file a claim for shipping damages. (Refer to FREIGHT DAMAGE for complete details.) Shipping damage is not covered by FS Curtis’s compressor warranty. 2. Ensure that adequate lifting equipment is available for moving the compressor equipment and clear a path to the installation location to avoid damage to property or compressor. 3. Turn off & lock out the electrical disconnect switch before working on the unit to prevent the unit from starting unexpectedly. 4. Read the compressor nameplate to verify the model and size ordered. 5. Read the motor nameplate to be sure the motor is compatible with your electrical conditions (volts, phase, and hertz). 6. Read the pressure relief valve nameplate to be sure it does not exceed the working pressure of the compressor or any other component in the system. 7. Read and understand the safety precautions contained within this manual. The successful and efficient operation of compressor equipment depends largely upon the amount of care taken to install and maintain the equipment. FS Curtis strongly recommends that any or all person(s) in charge of installing, maintaining, or servicing one of our compressors read and understand the entire contents of this manual and the respective compressor installation and operating instruction manual in order to perform such duties safely and efficiently. 8. Remove all packing plastic, foam and shipping related materials.

FREIGHT DAMAGE

The transportation industry has adopted a modification with regard to the handling of obvious and concealed damage claims. Therefore, it is extremely important that you examine every carton and crate as soon as you receive it. If there is any obvious damage to the shipping container, have the delivering carrier sign the freights bill, noting the apparent damage, and request a damage report. If concealed damage is discovered at a later date, the carrier must be notified within 15 days of initial receipt of freight. Contact the carrier as soon as possible, giving them an opportunity to inspect the shipment at the premises where the original delivery was made. Retain all containers and packing for inspection by the carrier. Do not move the freight. Concealed shipping damage is not covered by the FS-Curtis warranty. A claim form can be requested from the carrier. Your claim will need to be substantiated with the following documents. -Original bill of lading -Original paid freight bill -Original invoice or certified copy -Other particulars obtainable in proof of loss or damage (photos, damage inspection report, etc.) We suggest these instructions be circulated to your shipping and receiving personnel.

Installation Procedure

Step 1 – Select a proper location for installation Select a clean, dry, well lit area with a rigid floor strong enough to support the compressor and with adequate ventilation. Avoid placement of the compressor in an area that is excessively hot, dusty, humid or contaminated with foreign gases such as ammonia or acid fumes. The unit should never be operated at ambient temperatures above 104°F or below 32°F. If the ambient temperature is below 40°F, FS Curtis recommends using Arctic oil. Maintenance checks are required daily, thus three (3) feet of space needs to be provided around the compressor for proper inspection.

Note – If the unit or air intake is to be located outdoors, please contact Clark Heintz Tools & Equipment, LLC, authorized distributor, for additional instructions.

Step 2 – Remove the skid Remove and discard the shipping skid. The compressor should NEVER be operated on a skid.

Step 3 – Prepare the mounting surface If you wish to utilize an installation method other than the approved methods displayed in this manual, please contact Clark Heintz Tools & Equipment, LLC, authorized distributor. FS Curtis neither states as fact, nor implies that the above list of Acceptable/Unacceptable mounting is all-inclusive.

Step 4 – Install Vibration Isolator pads and mount the compressor Exposure to excessive vibrations can significantly shorten the life of the compressor. FS Curtis highly recommends mounting the unit on vibration isolator pads and the compressor should NEVER be operated without being securely fastened to the ground. Using a level, please check for proper alignment of the compressor. Uneven installation will unbalance the compressor leading to excessive noise, vibrations, and wear. Place a steel shim between the concrete and vibration pads and shim down as necessary for leveling. Level the compressor so it can be bolted down securely. Before tightening the bolts, check to see that all four feet are resting on the foundation. See fig (5) for mounting instructions for a floor stud, and see fig (6) for mounting instructions for an anchor bolt. [see diagram] Recommended Installation – Use concrete anchor bolt

Step 5 – Tighten the fasteners Incrementally tighten the mounting bolts evenly in a cross pattern. If necessary, after start up, continue incrementally tightening the mounting bolts in a crossing pattern until vibrations have been reduced to an acceptable level. After vibrations have been minimized, loosen ONE mounting bolt. The unit expands and contracts with changes in temperature, leaving ONE bolt loosened will allow for thermal expansion of the unit, reducing thermal stresses and vibrations on the tank. If after loosening one bolt the vibrations get worse, retighten bolt and select a different unit. Excessive vibrations can damage equipment.

Step 6 – Install piping network Run a clean pipe to the tank discharge opening, bushing up or down as necessary with clean bushings and fittings. Note that the more bushings and fittings placed in the air distribution system, the greater the opportunity for air leaks and breaks. FS Curtis recommends the installation of drip legs in the distribution line. Always install a safety relief valve in the distribution line between the compressor unit and in-line shutoff valves. If more than one compressor pumps into a common system, a check valve in the distribution line of each compressor unit is recommended to prevent moisture from entering the cylinder head(s) when one compressor is idle. A globe or gate valve (WOG rated) installed in the discharge line will allow compressor isolation from plant air system for compressor maintenance. (Note: A safety relief valve should be located between the compressor and the globe/gate valve.)

Step 7 – Install Compressor Intake (IF APPLICABLE) If the compressor intake is to be located away from the unit, please use the following instructions to ensure safe and efficient operation. Run a clean pipe to the compressor suction opening, bushing up or down as necessary with clean bushings and fittings. Note that the more bushings and fittings placed in the intake line, the greater opportunity for air leaks and breaks. If the run is over 10 feet in length, use a larger pipe diameter to avoid excessive pressure drops. When installing the pipes, please pitch the piping down and slightly away from the intake, to ensure that debris and condensation drains away from the compressor.

Post Installation Checklist

WARNING! Failure to perform the post installation checklist may result in mechanical failure, property damage, serious injury or even death.

Steps 1 through 9 should be performed prior to connecting the unit to a power source. If any condition on the checklist is not satisfied, make the necessary adjustments or corrections before starting the compressor.

1. Remove all installation tools from the compressor and check for installation debris. Abrasive dust can seriously damage the air intake and belt assemblies.

2. All FS Curtis compressors are shipped from the factory filled with the required amount of Curtis Lube Plus Compressor Lubricant specially formulated for Curtis Compressors. The oil level should register in the center of the oil sight glass or between the high and low marks on the dipstick. For additional lubricant contact Clark Heintz Tools & Equipment, LLC, authorized distributor. Failure to use authorized lubricant will void the manufacturer’s warranty.

3. Check inlet-piping installation.

4. Check all pressure connections for tightness.

5. Make sure all pressure relief valves in the air distribution are correctly installed.

6. Make sure all guards are in place and securely mounted.

7. Open all manual shutoff valves at and beyond the compressor and tank discharges.

8. Check and tighten all connections (mechanical and electrical) as they may have loosened during shipment. 9. After all the above conditions have been satisfied, the unit can be connected to the proper power source.

Electrical Requirements

TANK MOUNTED UNITS

The electrical installation of this unit should only be performed by a qualified electrician with knowledge of the National Electrical Code (N.E.C.), O.S.H.A. code and/or any local or state codes having precedence. All FS Curtis tank-mounted compressors come with a factory installed, pre-wired starter, if you wish to provide your own starter, please contact your local distributor for more information. Check the electrical supply for voltage, phase, and frequency to see that they match the nameplate stampings on the motor, magnetic starter, solenoids, and other controls. Before attempting to service electrical systems, ensure that maintenance personal are properly qualified, and service procedures comply with NFPA 70-1984, National Electrical Code, National Electrical Safety Code, as well as any applicable state and local regulations. Failure to abide by the national, state and local codes may result in physical harm and/or property damage and will void the manufacturer’s warranty.

DANGER! High voltage may cause personal injury or death, per O.S.H.A. regulations 1910.137, disconnect and lockout/tagout all electrical power supplies before opening the electrical enclosure or servicing.

WARNING! Never assume a compressor is safe to work on just because it is not currently operating. It could restart at any time. Follow all safety precautions outlined in the Safety Precautions section. NEMA electrical enclosures and components must be appropriate to the area installed. Safety and efficiency are the primary concerns when selecting components for compressed air systems. Products of inferior quality can not only hinder performance of the unit, but could cause system failures that result in bodily harm or even death. Select only top quality components for your system. Call Clark Heintz Tools & Equipment, LLC, FS Curtis Distributor, for quality parts and professional advice.

CAUTION! Turn off and lockout/tagout the main power disconnect switch before attempting to install the unit.

NOTE: At installation, the customer is to provide disconnect, branch circuit over-current protection, and grounding between the power supply and the electrical control enclosure in accordance with the National Electric Code and/or any local codes.

Start Up Pre Start Check List WARNING! Do not proceed until the PRE-STARTING CHECKLIST and sub-section has been read and is thoroughly understood.

1. Check oil level in crankcase for proper level.

2. Drain liquid from the air receiver and moisture trap (if so equipped).

3. Check system pressure. Do not operate the compressor in excess of the A.S.M.E. pressure vessel rating for the receiver or the service rating of the compressor, whichever is lower.

4. Check cooling fan rotation. Fan blades of the compressor flywheel force ambient air across fins of the intercooler and cylinder heads.

5. Check all pressure relief valves for proper operation.

6. Check control system for proper operation and to ensure all connections (mechanical and electrical) are properly tightened.

7. Jog the starter switch to check the rotational direction of the compressor. The flywheel should rotate in the counterclockwise direction (as viewed when facing the flywheel).

INITIAL STARTING & OPERATION

This instruction manual, as well as any instructions supplied by manufacturers of supporting equipment, should be read and understood prior to starting the compressor. If there are any questions regarding any part of the instructions, please call your local FS Curtis distributor. With the pre-starting checklist completed and satisfied, close the disconnect switch and start the compressor (for electric units) or engage the starter (for gas units). Watch and listen for excessive vibration and strange noises. If either exists, stop the compressor, look for and correct the problem before re-starting. Observe compressor operation closely for the first eight hours of operation. If any abnormal conditions are witnessed, stop the compressor and correct the problem. After two days of operation check belt tension, oil level, and inspect the system for leaks. Additionally, all electrical connections and mechanical fasteners should be checked for tightness and torqued as needed.

START-UP If the compressor is equipped with an automatic start-stop control (with pressure switch unloading), it is automatically unloaded upon starting, and will automatically load after attaining running speed. Simply throw the power switch to start the unit. If the compressor is equipped with a pilot valve, the pilot valve must be manually unloaded prior to starting the compressor.

Maintenance For the first weeks, the compressor needs time to “break in.” The belt requires time to stretch and fit into the surface of the pulleys. The piston rings need time to seat themselves into the cylinder walls, and bearings need to wear into place. For the first 100 hours or so, the compressor will consume higher than normal amounts of oil until the break in process is complete.

FIRST MONTH MAINTENANCE Check oil level at the beginning of every week, fill as needed, see oil subsection. Check belt tension at the beginning of each week and tighten as required, see belt tension subsection. Check bolts, pulley clamp screws, and jam nuts for tightness. Torque if necessary (see bolt torques subsection)

Shut Down Procedure The following procedures should be followed when stopping the compressor for maintenance or service.

WARNING! Never assume a compressor is safe to work on just because it is not operating. It could start at any time. 1. Per O.S.H.A. regulation 1910.147; The Control of Hazardous Energy Source (Lockout/Tagout); disconnect and lockout the main power source. Display a sign in clear view at the main power switch that the compressor is being serviced. 2. Isolate the compressor from the compressed air supply by closing the manual shutoff valve upstream and downstream from the compressor. Display a sign in clear view at the shutoff valve stating that the compressor is being serviced. 3. Lock open a pressure relief valve within the pressurized system to allow the system to be completely de-pressurized. NEVER remove a plug to relieve the pressure. 4. Open all manual drain valves within the area to be serviced. 5. Wait for the unit to cool before starting to service. (Temperatures of 125°F can burn skin. Some surface temperatures exceed 350°F when the compressor is operating.

Maintenance Schedule To assure maximum performance and service life of your compressor, a routine maintenance schedule should be developed. A sample schedule has been included to help you develop a maintenance schedule designed for your particular application. Time frames may need to be shortened in harsher environments or during periods of extremely heavy use. Make copies of this checklist and retain copy of the checklist, enter dates and maintenance person’s initials in the appropriate spaces. Makes copies of this checklist and retain copies of the completed checklists for potential warranty purposes. Enter the dates and maintenance person’s initials in the appropriate spaces. Keep the checklist and this Operations Manual readily available near the compressor.

DAILY MAINTENANCE Check oil level. Check oil for discoloration and filth. Drain oil and replace if required. Drain drip legs and traps in air distribution system. Open drain cock located at the bottom of the tank to relieve condensation. Drain intercooler (Large Industrial) Check for oil leaks.

WEEKLY MAINTENANCE Manually operate the pressure relief valves to be certain they are working. Clean the cooling surfaces of the intercooler and compressor. Check the compressor for air leaks. Check the compressed air distribution system for leaks. Check Oil Pressure, record reading at oil change (Large Industrials)

MONTHLY MAINTENANCE Check motor belt tension. Check fan belt tension (C200, C260, and C300). Check bolt torques, pulley clamp screws, and jam nuts for tightness. Torque if necessary. Inspect entire air distribution system for leaks. Check all connections (mechanical and electrical) and tighten as necessary.

EVERY THREE MONTHS Change oil (more frequently in harsher environments). Inspect valves for rust, wear, and carbon build up Check air filter for cleanliness and replace if necessary Replace Oil filter and clean oil strainer EVERY SIX MONTHS Replace air filter

OIL

OIL RECOMMENDATION

All FS Curtis MasterLine compressors require a 500 hour break in period with RC-1000 oil and are factory filled with the needed lubricant for the break in period. After the break in period is complete, drain the oil and replace with required oil for your compressor listed below. FS Curtis manufactures two different lubrication systems for Masterline compressors. The compressors D96, D97, C79, C89, C98, and C100 use an oiling ring system. Use ISO68 RC-1000 Premium Reciprocating Compressor Lubricant. This oil is specially formulated for Curtis Reciprocating Air Compressors and includes non-Detergent type with anti-foam, anti-rust and oxidation inhibitors. Use ISO100 RC-1000A for break in and regular use if ambient air temperatures exceed 90°F. Large industrial units C200, C260, and C300 use an oil pump system and operate under very high pressures and temperatures. For Large Industrials C150H, C260H, and C300H, use ISO100 RC-1000S synthetic oil. For all other large industrials, use ISO68 RC-1000. This oil is specially formulated for FSCurtis Compressors and includes non-Detergent type with anti-foam, anti-rust and oxidation inhibitors.

1. For proper lubrication the compressor shall not be operated below the minimum or above the maximum R.P.M. recommended for the various models.

2. Maintain oil level mid-way between the upper and lower lines of the crankcase sight gage.

3. Stop compressor to add and gauge oil. 4. Do not fill above the upper line and do not operate compressor with oil level below the lower line.

NOTE: ISO100 RC-1000S synthetic oil is available as an option on all Masterline Compressors. Using synthetic oil will significantly extend the life of your compressor.

Oil Pressure Large Industrials (C200 and up)

Base mounted large industrial units are equipped with a factory installed oil pump and oil pressure gauge. Proper oil pressure readings are as follows

Oil Gauge Pressure

Normal Pressure ............... 28 to 30 PSIG Minimum Pressure ............ 20 PSIG Switch Cutoff Pressure ..... 18 PSIG

Oil Switch

The oil pressure safety switch is set and tested at the factory for 18 pounds minimum oil pressure. If the oil pressure is below the set pressure, the safety switch will cause the power to shut off. After correcting the problem, power can be restored by the following procedure: 1. Push reset button on the pressure switch. 2. Push start button on starter.

Oil Pressure Procedure

Stop compressor and turn off power, then drain oil from crankcase. When facing flywheel, remove the right hand side door from crankcase to expose closure screw in bearing plate No. CM-836. Remove closure screw – No. CM-843 for models 200, 260, and 260H No. CM-924 for models 300 and 300H Add Curtis-Toledo part #CM-1073-2, steel slug. Insert slug in opening, flat against end of spring VO-103 in position between spring and closure, tighten closure screw. Under normal conditions the addition of this slug will increase the oil pressure 4 to 5 pounds. Return side door, restore oil level in crankcase (check oil level) and start compressor. Note Oil Pressure Gauge, if normal pressure of 28 to 30 pounds is not obtained by the above procedure contact factory service department. Follow the above instructions to expose closure screw. Note: 1/2” dia. Hex hollow head adjusting setscrew with lock nut in the closure screw, see drawing LH-32.

To adjust oil pressure 1. Loosen lock nut. 2. To increase pressure – turn set screw to the rig2. To increase pressure – turn set screw to the rig 3. To lower pressure – turn set screw to the left (loosen). Note – under normal conditions one full turn of the set screw will change the oil pressure approximately 4 pounds. Hold set screw position and tighten lock nut. Return side door, restore oil level in crankcase (check oil level) and start compressor. “Note Oil Pressure Gauge” if normal pressure 28 to 30 pounds is not obtained by the above procedure contact factory service department.

BELT TENSION CAUTION: Over tightening the v-belt(s) will result in overloading of the motor, and/or belt and pulley failure. A loose belt will result in an unstable speed, premature belt wear, “throwing” belts and a high amp draw. To change tension, turn the adjusting bolt at the end of the base. Retighten motor hold-down bolts. Grease both the motor and compressor pulleys once a year with lithium ball bearing grease. Proper belt tensioning requires the use of a belt tension gauge to measure belt tension. This tool is available at your local auto parts or hardware store.

BELT TENSIONING INSTRUCTIONS 1. Loosen the motor mounting bolts, but do NOT remove the nuts. See fig (12) in manual for the mounting bolt locations. Do NOT attempt to adjust the take-up bolt before loosening all of the motor mounting bolts, attempting to do so will damage the unit. 2. Consult table (7) for the appropriate deflection and tension values for challenge air units. Table (8) contains deflection and tension values for CT units. 3. At the center of the span, perpendicular to the belt, apply pressure to the outer surface of the belt tension gauge as shown in figure (13). Apply force to the belt until the rubber ring on the deflection gauge is located at the original position of the belt. Record the reading on the belt tension gauge and compare to the chart. Reset the rubber ring on the belt tension gauge before taking another reading. 4. Adjust the take-up bolt to tighten or loosen the belt tension as required. 5. Finger-tighten ONE motor mounting bolt. Using a straight-edge, check that pulleys are aligned and adjust motor as necessary. 6. Finger tighten the remaining motor mounting bolts. 7. Using a wrench or air tool, incrementally tighten the mounting bolts in a basic crossing pattern. 8. Re-mount the belt guard. DO NOT attempt to operate the unit without the belt guard securely in place. 9. Recheck the tension of the new belts several times in the first month of operation and adjust if necessary. Thereafter, check belt tension every three months.

Unloader Maintenance Automatic Start-Stop with Pressure Switch Operation (Compressors, C79, C89, D96, D97 and C98) A compressor equipped for start-stop (pressure switch) operation has a centrifugal unloading mechanism or a solenoid valve piloted suction valve unloader to provide an automatic unloaded start. This serves to prevent the compressor from starting against discharge line pressure. The various methods are as follows: Solenoid Valve Piloted Suction Valve Unloading (Compressors D96, C79, C89, D97, C98) These models are provided with air pressure actuated suction valve unloaders such that when air pressure is supplied to the unloader the suction valve is held open, and the compressor cannot pump even though running. To provide automatic start-stop operation with an unloaded start on these models, a 3-way solenoid valve with a restricted exhaust and a pressure switch are used to achieve the following sequence of operation. If the compressor shuts down or stops because the pressure switch opens, the solenoid valve is de-energized permitting air pressure from the receiver to act on the unloaders. This unloads the compressor. When the compressor is started again or the pressure switch closes, the solenoid valve is energized which permits air from the unloader to exhaust through the restrictor plug. The restrictor plug delays the loading action of the compressor until it has reached operating speed.

Constant Speed Control (All compressors) A compressor unit set up to run continuously has an unloading mechanism to stop the unloading mechanism to stop the pumping action of the compressor at a predetermined cut-out pressure and start the pumping action at some lower pre-determined cut-in pressure. This unloading cycle is accomplished by one of the following ways. On single stage and some two stage compressors. The suction valves are held open during the unloading cycle. On some two-stage compressors, the low stage suction valve is held open while a by-pass valve unloads the high stage during the unloaded cycle. These methods employ air pressure from the discharge line or receiver to actuate unloader pistons which actuate the unloading mechanism. Control of the air pressure to and from the unloaders is accomplished by either an air pressure actuated pilot valve or by a three-way solenoid valve controlled by a pressure switch. The electric motor must also be started no more than six (6) times per hour to provide adequate motor life.

Constant Speed Controls with Piston Type Unloaders (All compressors) The unloaders are of “O” ring and piston type with pressure and over travel compensating spring. This in turn contacts the valve which has a built in unloader fork and return spring. To check to see if unloader is stuck open or closed the action can be viewed on the low-pressure cylinders by removing air inlet filter and elbow and watching the operation through the inlet opening. If the piston unloader becomes sticky or jerky in operation, remove the unloader cylinder and piston assembly. Remove all dirt or carbon and lubricate the piston and cylinder with a high temperature bearing grease before re-assembly and installation.

CONSTANT SPEED CONTROL with PILOT VALVE (All compressors) The pilot valve supplied with some compressor units is a spring-loaded ball and seat type. When air receiver pressure reaches the pre-set (adjustable) cut-out pressure, the ball is unseated permitting air pressure to actuate the unloaders. When the air receiver pressure drops to the cut-in pressure, the ball reseats and relieves the pressure acting on the unloaders permitting the compressor to pump again. These valves have a manual override device consisting of a screw or cam located at the exposed end of the stem, which forces the stem outward. This permits manual unloading and reloading of the compressor unit. Should these valves become faulty in operation, they may require disassembly and cleaning (especially the filter). After reassembly, the pressure settings (cut-out and cut-in) must be readjusted.

INSTRUCTIONS UNLOADER PILOT

VALVE FUNCTION VV1002 Pilot Valve senses receiver (tank) pressure when the receiver pressure rises to the preset “unload” valve setting, the ball opens passing high pressure air to the compressor unloading device. When the receiver pressure drops to the preset “load” valve setting, the ball closes venting the compressor-unloading device to atmosphere. A manual override permits manual unloading of the compressor when placed in the up position.

INSTALLATION Receiver (tank) pressure is connected to the 1/4” pipe thread inlet. The compressor-unloading device is connected to the 1/8” pipe outlet.

ADJUSTMENT PRESSURE ADJUSTMENT – The pilot valve is preset at assembly to a specified cutout and differential. A limited adjustment of the unload pressure may be made in the field. To adjust the unload pressure, unlock the locking nut (B), and turn the adjusting nut (A) clockwise for higher pressures and counterclockwise for lower pressures.

CAUTION – As unload pressure is increased, the pressure differential between load and unload pressure will become larger. As unload pressure is decreased, the pressure differential will become smaller. A 30 PSI change in unload pressure will change the differential approximately 10 PSI. Therefore large changes in pressure adjustment must not be made without adjusting the differential. A minimum differential of 10 PSI should be maintained to prevent system from loading and unloading too frequently.

DIFFERENTIAL ADJUSTMENT – To increase the differential, unlock locknut (D), then turn cap nut (C) very slightly clockwise – not more than 1/4 of a turn at time. To decrease the differential, repeat above, but instead turn cap nut (C) counterclockwise. It may be necessary at this point to fine adjust the unload pressure as outlined in the Pressure Adjustment by turning the adjusting nut (A) in the proper direction.

MAINTENANCE – If the pilot valve becomes erratic or fails to operate after being in use for some time, it should be disassembled, cleaned and reassembled. If the locknut (B) is loosened a minimum amount before removing adjusting nut (A), it will assist in adjusting the pressure setting on reassembly.

MAIN BEARING The main bearings are of the tapered roller type and must be shimmed or adjusted for end play as follows: 0.0005” to .002” for compressors D96, C79, C89 and D97. 0.0005” to .003” for compressors C98 and C100 0.002” to .004” for compressors C150, C200 and C260 0.004” to .006” for compressors C300

Maintenance Parts and Rebuild Kits To order replacement parts for routine maintenance, please contact authorized distributor Clark Heintz Tools & Equipment, LLC. PLEASE NOTE: TO SAVE ON SPACE, DIAGRAMS AND SKETCHES HAVE BEEN OMITTED FROM THIS MANUAL POSTED TO OUR BLOG. PLEASE CHECK OUT THE PDF VERSION OF THIS MANUAL HERE: https://www.nhproequip.com/PDFs/Curtis-ML-Air-Compressor-Series-Manual.pdf

L Series Air Compressor

L Series Air Compressor