- Register

- Log in

- Wishlist (0)

- My Cart (0) You have no items in your shopping cart.

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2011

- 2010

Blog

Here is a list of motorcycle rallies, rides and events going on throughout the US (there are some Canadian rides listed, as well, though it's not as comprehensive as the U.S. listing. Please feel free to drop a note to me through the blog with any additions. March 1 March 1 Big Swamp Harley Davidson Boot Clinic Opelika, AL March 1 Hot Winter Nights Benton, AR March 1 American Legion Riders Post 61s Shoot n Ride Avondale, AZ March 1 Ride Against Lyme - Benefit Motorcycle Ride and Car Run Peoria, AZ March 1 Crazy Earls Red and White Support Run Yuma, AZ March 1 West Side Show and Shine Modesto, CA March 1 Breast Cancer Run for Randy San Diego, CA March 1 Iron Steed Motorcycle Cleaning Workshop Vacaville, CA March 1 Victory Demo Days Brea, CA March 1 Service Seminar at High Country Harley Davidson Frederick, CO March 1 Michael Mickey McGinley 5th Annual Poker Run Panama City, FL March 1 Riding Gear Essentials Workshop Panama City Beach, FL March 1 Memorial Ride Port Charlotte, FL March 1 Honor Flight Poker Run and Pre Daytona Biker Bash 1st Annual Venice, FL March 1 Volusia County Biker Rights Rally Daytona Beach, FL March 1 1st Annual Honor Flight Poker Run and Pre-Daytona Biker Bash Venice, FL March 1 Barney's 7th Annual Summer Kickoff Parts Unlimited - Tampa, FL March 1 Pre Bike Week Party Clermont, FL March 1 Pre-Heating Bike Week Haines City, FL March 1 Iron Pigs MC - St. Johns River Chapter Monthly Meeting Orlando, FL March 1 ALR Post 129 Bike Night - Jacksonville Beach, FL March 1 Bike Night Pam & Phil @ Extreme Sports Park Clermont, FL March 1 Bikini Bike Wash and Pre-Daytona Bike Week Party Kissimmee, FL March 1 Sleepy Hollow Biker Day Floral City, FL March 1 Hot Rodz and Harleys Columbus, GA March 1 Chattahoochee Harley Davidson Eyewear Clinic Columbus, GA March 1 NE Georgia Swap Meet Commerce, GA March 1 Ride For Randall Baldree Locust Grove, GA March 1 Monster Energy AMA Supercross Indianapolis, IN March 1 Rolling Thunder KY Ch 2 Chili Supper and Live Auction Glasgow, KY March 1 AHRMA Vintage Motocross - Desoto Motorsport Park Grand Cane, LA March 1 New Rider Boot Camp Raleigh, NC March 1 MDA Black and Blue Ball 7th Annual Philadelphia PA March 1 Demo Day at Harley Davidson of Greenville Greenville, SC March 1 Blessing of the Bikes Charleston SC March 1 Texas Independence Day Party College Station, TX March 1 Spring Rally Kick Off Party Houston, TX March 1 Patriot University Tire Service Seminar Fairfax, VA March 1 Ladies of Harley Jambalaya Cook-Off Portsmouth, VA March 1 LOH Jambalaya Cook-Off Portsmouth, VA March 1 Euro Moto Motorcycle Show Lynnwood, WA March 1 - 2 Penton Racing Products National Cross Grand Cane, LA March 1 - 2 Nuclear Cowboyz Freestyle Tour East Rutherford, NJ March 1 - 2 AMA Arenacross Series Tulsa, OK March 1 - 4 Guinness World Record Mini Bike Attempt Clarksville, TN March 2 March 2 Biker Breakfast National City, CA March 2 Sunday is All Day Bike Day at Peggys Corral Palmetto, FL March 2 Screwie Louie's Porpoise Pub's BIKER SUNDAYS Seminole, FL March 2 Webster Westside Swap Meet & Show Webster, FL March 2 Bike Night Pam @ Tijuana Flats Leesburg, FL March 2 Charlotte's Webb Biker Day Wauchula, FL March 2 Sleepy Hollow Biker Day Floral City, FL March 2 Dirty Harrys 1st Sunday BBQ Daytona Beach, FL March 2 Boone County Vintage Metric Motorcycle and Scooter Swap Meet and Auction Lebanon, IN March 2 AHRMA Post Vintage MX - Desoto Motorsport Park Grand Cane, LA March 2 Faribault Harley Davidson HOG Garage Party Faribault, MN March 2 Jeff Williams Motorcycle Swap Meet Sedalia, MO March 2 Sunday Biker Pancake Breakfast Tigard, OR March 3 March 3 M.N.O. Monday @ Porpoise Pub - Musicians Night Off / Monday Night Out! - Seminole, FL March 4 March 4 San Diego Bike Night San Diego, CA March 4 Big Papa's Pit Bike Night Tampa, FL March 4 Bike Night Pam & Phil @ The Bar Ocoee, FL March 4 Screwie Louie's Fat Tuesday Party Cajun Music, Food, & Fun! - Seminole, FL March 4 Venom2 Bike Night - Hudson, FL March 4 Iron Cross Motorcycles Bike Night West Palm Beach, FL March 4 Texoma Harley Davidson Womens Garage Party Sherman, TX March 5 March 5 Ride to Doolittles in Cuba City, Wisconsin Dubuque, IA March 5 Illinois Harley Davidson Service Seminar Countryside, IL March 5 Bike Night Pam @ Beef O'Brady's Clermont, FL March 5 Big Dawg 3 Bike Night Davie, FL March 5 Olde Fish House Marina Matlacha, FL March 5 Popeyes Bike Night LaBelle, FL March 5 Raccoons Bike Night Valrico, FL March 5 Rudy's Crossroads Bike Night Deland, FL March 5 - March 9 The Ultimate Outdoor Experience-Long Beach Long Beach, CA March 6 March 6 Glendale Harley Davidson Ladies Garage Party Glendale, CA March 6 Bike Night on the Bay Long Beach, CA March 6 Motorcycle Boot Camp Aurora, CO March 6 Manatee River Bike Night Bradenton, FL March 6 Black Widow Bike Night Port Charlotte, FL March 6 Bike Night at Whiskey River Saloon Port Orange, FL March 6 Renegades Bar and Grill Bike Night West Palm Beach, FL March 6 Bike Night Pam @ Buffalo Wild Wings Clermont, FL March 6 Back Room Bar & Grill Bike Night New Port Richey, FL March 6 Bike Night At The Back Room Bar & Grill New Port Richey, FL March 6 Ladies Only Garage Party Charleston, SC March 6 - 9 Stock Law Gap Rally Georgiana, AL March 6 - 17 Waterfront Sportsman Rally Point for Daytona Bike Week Mebane, NC March 7 March 7 Motorcycle Boot Camp San Diego, CA March 7 36th Annual Daytona Bikeweek Swapmeet Daytona Beach, FL March 7 Bike Night with Phil @ VFW Winter Garden, FL March 7 Bike Week 2014 ABATE Campground Deland, FL March 7 AMVETS 44 Riders Big Azz Steak Dinner Plant City, FL March 7 Bike Night Pam @ Rock Springs Bar and Grill Apopka, FL March 7 BIKE NIGHT EVERY 1ST AND 3RD FRIDAY Gibsonton, FL March 7 Bike Week Trifecta Inlet Harbor Restaurant - Ponce Inlet, FL March 7 Radio Bar and Grill Friday Bikes & Bands Night Tampa, FL & LIVE ONLINE March 7 Screwie Louie's Bike Week KickOff - Best Buns Contest! w/ ZigZag Seminole, FL March 7 Cacklebery Campground Bike Week New Smyrna Beach, FL March 7 Daytona Bike Week Daytona, FL March 7 Bike Night at Baymeadows Jacksonville, FL March 7 Motorcycle Ride for Lunch Bedford, TX March 7 Mardi Gras Bike Nite Carrollton, TX March 7 - 8 Sunshine National Swap Meet New Smyrna Beach, FL March 7 - 9 Ride for the Warrior III Casa Grande, AZ March 7 - 9 International Vintage Motorcycle Meet and Bike Show 3rd Annual Eustis, FL March 7 - 9 AMA Arenacross Series Albuquerque, NM March 7 - 11 Orlando Harley Davidson Demo Days Kissimmee, FL March 8 March 8 Advanced Motorcycle Skills Training Trussville, AL March 8 Hogs N Dogs Bellemont, AZ March 8 Hogs N Dogs Mayer, AZ March 8 McCarthy Building Companies 2014 Ride for Sight Mesa, AZ March 8 McCarthy Building Companies 2014 Charity Ride Ride For Sight Mesa, AZ March 8 Barger Performance Workshop Canoga Park, CA March 8 Jamestown Swap Meet 18th Annual Jamestown, CA March 8 Fried Chicken Cook Off Lathrop, CA March 8 Bullet Memorial Run San Diego, CA March 8 Womens Harley Davidson Garage Party San Marcos, CA March 8 Port Stockton Motorcycle Club Gold Rush Run - 35th Annual Stockton, CA March 8 Mile High Harley Davidson Performance Workshop Aurora, CO March 8 Orlando Bike Week 2014 Orlando, FL March 8 Suncoast Brotherhood HOWL AT THE MOON POKER RUN Dunedin, FL March 8 Daytona Supercross - Daytona Bike Week Daytona Beach, FL March 8 Shovelhead Bike Show - Daytona Bike Week Deland, FL March 8 Bike Week Kick-Off Car and Bike Show - Daytona Bike Week Palm Bay, FL March 8 Freedom Ride Poker Run and Bike Show Venice, FL March 8 Ellie Lee & The Blues Fury Live @ The Porpoise Pub Seminole, FL March 8 Cacklebery Campground Bike Week New Smyrna Beach, FL March 8 Daytona Bike Week Daytona, FL March 8 Ocala Motorcycle & Car Swap Meet Ocala, FL March 8 ASRA Team Challenge Series - Roebling Road Raceway Bloomingdale, GA March 8 Daytona Pit Stop Party Tifton, GA March 8 Chilly Chaps Ride Meridian, ID March 8 Mardi Gras Party Meridian, ID March 8 Northern Illinois ABATE Cabin Fever Party & Membership Drive Lake Villa, IL March 8 Alefs Harley-Davidson Tips with the Techs Workshop Wichita, KS March 8 Alefs Tips with the Techs - Bike Detailing Workshop Wichita, KS March 8 Kingsman MC Annual Screw Daytona Party Shady Side, MD March 8 Chili Cook-Off St Joseph, MO March 8 St Joe Harley Davidson Service Seminar St Joseph, MO March 8 Kawasaki Customer Appreciation Day Raleigh, NC March 8 Daytona Bike Week Kick-Off Party Meredith, NH March 8 Breakfast Behind Bars Oklahoma City, OK March 8 Harley Davidson Demo Day Greenville, SC March 8 Law Riders MC Oyster Roast 18th Annual Ladson, SC March 8 Dallas Harley-Davidson Clinic: Boom! Audio Workshop Garland, TX March 8 - 9 Parts Unlimited Mud Mucker GNCC Bunnell, FL March 8 - 9 Nuclear Cowboyz Freestyle Tour Orlando, FL March 8 - 9 ASRA Sprint Series - Roebling Road Raceway Bloomingdale, GA March 8 - 9 Wilmington Northeast Motorcycle Expo Wilmington, MA March 8 - 17 The Black Cloud Saloon - Daytona Bike Week 2014 Bunnell, FL March 9 March 9 Hawg Heaven Church Service National City, CA March 9 Free Sober Hog Roast and Live Music - Daytona Bike Week Bunnell, FL March 9 Sunday is All Day Bike Day at Peggys Corral Palmetto, FL March 9 Screwie Louie's Porpoise Pub's BIKER SUNDAYS Seminole, FL March 9 6th Annual Bahia Shrine Sam Swope Charity Ride ORLANDO, FL March 9 Orlando Bike Week 2014 Orlando, FL March 9 Women Blessing Women - Annual Bike Blessing Edgewater, FL March 9 Cacklebery Campground Bike Week New Smyrna Beach, FL March 9 Daytona Bike Week Daytona, FL March 9 The Roast of Victor w/ WAYLAND LIVE @ Screwie Louie's Porpoise Pub Seminole, FL March 9 Rat Bike Show - Daytona Bike Week Deland, FL March 9 Bike Week Chicken Fest - Daytona Bike Week 2014 Deland, FL March 9 Sam Swope Charity Ride for Shriners Hospitals - 6th Annual Orlando, FL March 9 All Rod Show 1st Annual Palm Bay, FL March 9 St Pattys Day Poker Run Benefitting Humane Society of Sarasota County Sarasota, FL March 9 AHRMA Dirt Track Racing - Oglethorpe Speedway Park Pooler, GA March 9 March Madness Last Chance before Spring Swap Meet Boone, IA March 9 GIANT Motorcycle Swap Meet Grand Rapids, MI March 10 March 10 Orlando Bike Week 2014 Orlando, FL March 10 Cacklebery Campground Bike Week New Smyrna Beach, FL March 11 March 11 High Country Motorcycle Boot Camp Frederick, CO March 11 Womens Garage Party at Texas Harley Davidson Bedford, TX March 11 Orlando Bike Week 2014 - Orlando, FL March 11 Screwie Louie's Porpoise Pub - All You Can Eat Shrimp & Crawfish Night! Seminole, FL March 11 Venom2 Bike Night Hudson, FL March 11 Cacklebery Campground Bike Week New Smyrna Beach, FL March 12 March 12 Ditch Work Ride Fresno, CA March 12 Orlando Bike Week 2014 Orlando, FL March 12 Big Dawg 3 Bike Night Davie, FL March 12 Olde Fish House Marina Matlacha, FL March 12 Raccoons Bike Night Valrico, FL March 12 Rudy's Crossroads Bike Night Deland, FL March 12 Cacklebery Campground Bike Week New Smyrna Beach, FL March 12 Daytona Bike Week Daytona, FL March 12 Heart Strings for Heroes Honors Fest Daytona Beach, FL March 12 Side Car and Trike Show - Daytona Bike Week Deland, FL March 12 Fort Myers Harley Davidson Ladies Garage Party Fort Myers, FL March 12 Biker Day at The Capitol 11th Annual St Paul, MN March 12 Greenville Bike Night Greenville, SC March 12 Roanoke Valley Harley Davidson Womens Garage Party Roanoke, VA March 13 March 13 Bike Night on the Bay Long Beach, CA March 13 Bike Night at Whiskey River Saloon Port Orange, FL March 13 Orlando Bike Week 2014 Orlando, FL March 13 Applebee's Bike Night Sarasota, FL March 13 Back Room Bar & Grill Bike Night New Port Richey, FL March 13 Bike Night At The Back Room Bar & Grill New Port Richey, FL March 13 Cacklebery Campground Bike Week New Smyrna Beach, FL March 13 Daytona Bike Week Daytona, FL March 13 Heart Strings for Heroes Honors Fest Daytona Beach, FL March 13 AHRMA Dirt Track Racing - Marion County Speeday Ocala, FL March 13 Motorcycle Boot Camp Columbia, MO March 13 - 15 Norman Swap Meet Norman, OK March 14 March 14 Riders Bike Night Trussville, AL March 14 Orlando Bike Week 2014 Orlando, FL March 14 Radio Bar and Grill Friday Bikes & Bands Night Tampa, FL & LIVE ONLINE March 14 Cacklebery Campground Bike Week New Smyrna Beach, FL March 14 Daytona Bike Week Daytona, FL March 14 Heart Strings for Heroes Honors Fest Daytona Beach, FL March 14 Motorcycle Boot Camp Fort Ann, NY March 14 Texas Harley Lunch Ride Bedford, TX March 14 Spring Dyno Shoot-Out/March Madness Portsmouth, VA March 14 - 16 Wild Wild West Bike Fest Winchester, CA March 14 - 16 WERA National Challenge Series - Roebling Road Raceway Bloomingdale, GA March 14 - 16 WERA Sportsman Series - Roebling Road Raceway Bloomingdale, GA March 14 - 16 Piston Power Show Cleveland, OH March 14 - 16 AMA Arenacross Series Hidalgo, TX March 14 - 16 March Madness/Spring Dyno Shoot Out Portsmouth, VA March 14 - 16 Inland Northwest Motorcycle Show Spokane, WA March 15 March 15 Preventitive Motorcycle Maintenance Clinic Opelika, AL March 15 Riders Harley Open House Trussville, AL March 15 Natchez Trace HD 2nd Annual Saint Patty's Party Tuscumbia, AL March 15 Saint Patty Party Fort Smith, AR March 15 Chester's Harley-Davidson Party on the Patio Mesa, AZ March 15 Annual Bike Blessing Mayer, AZ March 15 Mesa Police Department Motor Unit Escorted Ride Mesa, AZ March 15 Chili Cook Off 6th Annual San Diego, CA March 15 Luck of the Irish Poker Ride 3rd Annual San Marcos, CA March 15 Lords Prospects Motorcycle Ministry Bike Blessing Vacaville, CA March 15 St Pattys Day Ride Vacaville, CA March 15 24th Annual Super Show & Swap Meet Colorado Springs, CO March 15 Heart Strings for Heroes Canopy of Cards Poker Run Daytona Beach, FL March 15 Orlando Bike Week 2014 Orlando, FL March 15 Cacklebery Campground Bike Week New Smyrna Beach, FL March 15 Fox and Hounds Bike Night St. Patty's Day Weekend Party Brandon, FL March 15 Antique Bike Show Deland, FL March 15 Crimeline BBQ Cook-Off Palm Bay, FL March 15 Empty Canteen Poker Run and Scavenger Hunt - 6th Annual Acworth,GA March 15 Kelsi Long Memorial Ride Augusta, GA March 15 Riding Gear Essentials Workshop Bogart, GA March 15 Pink Ladies for Breast Cancer Awareness Columbus, GA March 15 St Patricks Day Party and Bike Show at MCHD Dalton, GA March 15 Open House at Woodstock Harley Davidson Woodstock, IL March 15 Alefs St Patty's Event Wichita, KS March 15 Sergeant Audie Murphy Club (SAMC) Poker Run Leesville, LA March 15 Nuclear Cowboyz Freestyle Tour New Orleans, LA March 15 Monster Energy AMA Supercross Detroit, MI March 15 Spring Open House at Faribault Harley Davidson Faribault, MN March 15 Ride With The King Motorcycle Ride and Rally Tupelo, MS March 15 Durham HOG 28th Annual Bike Show and Chili Cookoff Durham, NC March 15 New York City Harley Davidson St Patrick's Day Event Manhattan, NY March 15 St Patricks Day Party North Tonawanda, NY March 15 Summer Ride Series Kickoff Harrisburg, PA March 15 Harley Davidson of Greenville Demo Days Greenville, SC March 15 St Patricks Day Party and Bike show Chattanooga, TN March 15 Cowboy Harley Davidson Lot Party Beaumont, TX March 15 Snap-on Masters of Metal Tour Garland, TX March 15 St Patty's Day Party Grand Prairie, TX March 15 Texas Thunder Annual Chili Cook-Off Nacogdoches, TX March 15 Bikes and Beads Sherman, TX March 15 Blessing of the Bikes The Woodlands, TX March 15 St Patricks Day Ride Barre, VT March 15 - 16 Super Show and Swap Meet 24th Annual Colorado Springs, CO March 15 - 16 Penton Racing Products National Cross Country Series Chester, SC March 16 March 16 So Cal - CRUISE IN - Free Event Lake Elsinore, CA March 16 24th Annual Super Show & Swap Meet Colorado Springs, CO March 16 Colorado Tattoo Competition 22nd Annual Colorado Springs, CO March 16 Sunday is All Day Bike Day at Peggys Corral Palmetto, FL March 16 Screwie Louie's Porpoise Pub's BIKER SUNDAYS Seminole, FL March 16 Central Florida Motorcycle Swap Meet and Greet Kissimmee, FL March 16 Orlando Bike Week 2014 Orlando, FL March 16 Cacklebery Campground Bike Week New Smyrna Beach, FL March 16 Fox and Hounds Bike Night St. Patty's Day Weekend Party Brandon, FL March 16 Motorcycle Swap Meet St. Augustine, FL March 16 41st Annual Kalamazoo Swap Meet Kalamazoo, MI March 16 Faribault Harley Davidson Ladies Garage Party Faribault, MN March 16 Rides of March New Rochelle, NY March 16 St Patty's Day Ride Franklin, TN March 16 ABATE Region 2E 15th Annual Motorcycle Show and Swap Meet Menasha, WI March 17 March 17 Screwie Louie's St. Patty's Day Bash at the Porpoise Pub Seminole, FL March 17 Fox and Hounds Bike Night St. Patty's Day Weekend Party Brandon, FL March 18 March 18 Big Papa's Pit Bike Night Tampa, FL March 18 Venom2 Bike Night Hudson, FL March 19 March 19 High Country Harley Davidson Garage Party Frederick, CO March 19 Raccoons Bike Night Valrico, FL March 19 Rudy's Crossroads Bike Night Deland, FL March 19 Ride to Sharks in Elizabeth, Illinois Dubuque, IA March 19 High Desert Harley Davidson Garage Party Meridian, ID March 19 Alefs Harley Davidson Womens Garage Party Wichita, KS March 19 Bike Night at Harley Davidson of Greenville Greenville, SC March 20 March 20 Mobile Bay Bike Night Mobile, AL March 20 Bike Night on the Bay Long Beach, CA March 20 Mile High Harley Davidson Ladies Garage Party Aurora, CO March 20 Bike Night at Harley Davidson of Palm Beach West Palm Beach, FL March 20 Bike Night at Whiskey River Saloon Port Orange, FL March 20 Bike Night At The Back Room Bar & Grill New Port Richey, FL March 20 City Limits Harley Davidson Motorcyle Service Seminar Palatine, IL March 20 Woodstock Harley Davidson Garage Party Woodstock, IL March 20 Barb's Harley Davidson Womens Garage Party Mt. Ephraim, NJ March 20 Custom Bike Unveiling Long Island City, NY March 20 Bike Night at Jimbos Roadhouse Hockley, TX March 20 Screw Winter Party Barre, VT March 20 - 23 Bama Bike Fest Spring Motorcycle Rally Forkland, AL March 21 March 21 BIKE NIGHT EVERY 1ST AND 3RD FRIDAY Gibsonton, FL March 21 Radio Bar and Grill Friday Bikes & Bands Night Tampa, FL & LIVE ONLINE March 21 Bike Night Presented By A Ride For the Wounded Leavenworth, KS March 21 Texas Harley Davidson Lunch Ride Bedford, TX March 21 - 23 Spring Swap Meet, Bike/Car Show, and BBQ Cookoff Springfield, GA March 21 - 23 Iron Horse Bike Show Grand Island, NE March 22 March 22 Wheels for Wilmer Hall - 2nd Annual Mobile, AL March 22 Helping Honduras Ride Opelika, AL March 22 Habitat for Humanity Central Arizona Show and Shine for Shelter Car and Motorcycle Show 2nd Annual Apache Junction, AZ March 22 American Legion Riders Chapter 58 Bike and Hot Rod Show 5th Annual Fountain Hills, AZ March 22 Biggs Breakfast and Crew Ride San Marcos, CA March 22 American Legion Post 53 Poker Run Temecula, CA March 22 AHRMA Vintage Motocross - Motocross of Marion County Citra, FL March 22 AMSTAR Spangled Heroes Poker Run and Fund Raiser TRACK CHAIR INITIATIVE - Crystal River, FL March 22 LED Lighting Workshop Fort Myers, FL March 22 Place Tavern Biker Bash and Party Punta Gorda, FL March 22 Seminole Swap Meet Sanford, FL March 22 Music and Motorcycles Zephyrhills, FL March 22 Spring Thaw Countryside, IL March 22 Alefs Tips with the Techs - LED Wichita, KS March 22 Alefs Harley-Davidson Tips with the Techs Workshop Wichita, KS March 22 Clay Humane's Hogs for Dogs Bike Run - Orange Park, FL March 22 Spring Breakout 2nd Annual Marquette, MI March 22 Service Seminar at St Joe Harley Davidson St Joseph, MO March 22 Orphan Run High Point, NC March 22 Young Marines Poker Run Raleigh, NC March 22 Monadnock Harley Davidson Spring Open House Swanzey, NH March 22 Spring Fever Run Oklahoma City, OK March 22 Monster Energy AMA Supercross Toronto, ON CAN March 22 Open House at Timms Harley Davidson Anderson, SC March 22 Demo Day at Harley Davidson of Greenville Greenville, SC March 22 Harley Davidson of Dallas Demo Day Allen, TX March 22 The Breath of Life Biker Ball Springville, UT March 22 Dealer Ride NRV to Amelias Roanoke, VA March 22 - 23 Custom Motorcycle Show and Expo Mount Clemens, MI March 22 - 23 CMRA Road Racing - Texas World Speedway College Station, TX March 23 March 23 So-Cal Cycle Swap Meet Long Beach, CA March 23 AHRMA Post Vintage MX - Motocross of Marion County Citra, FL March 23 Forgotten Soldiers Outreach Poker Run Greenacres, FL March 23 Sunday is All Day Bike Day at Peggy's Corral Palmetto, FL March 23 Screwie Louie's Porpoise Pub's BIKER SUNDAYS Seminole, FL March 23 Cycle World Customer Appreciation Bogart, GA March 23 Walneck Motorcycle Swap Meet and Show St Charles, IL March 23 Pancake Breakfast Forked River, NJ March 23 GIANT Motorcycle Swap Meet Berea, OH March 23 Harrisburg Super Swap Meet Harrisburg, PA March 23 Coyote Motorcycle Swap Meet Fort Worth, TX March 24 March 24 Mathews Harley Motorcycle Boot Camp Fresno CA March 25 March 25 Venom2 Bike Night Hudson, FL March 26 March 26 Ditch Work Ride Fresno, CA March 26 High Country Harley Davidson Garage Party Frederick, CO March 26 Raccoons Bike Night Valrico, FL March 26 Rudy's Crossroads Bike Night Deland, FL March 26 Motorcycle Boot Camp Long Island City, NY March 26 American Harley Davidson Womens Garage Party North Tonawanda, NY March 26 South Carolina Bike Night Greenville, SC March 26 Motorcycle Boot Camp Garland, TX March 26 Bike and Steak Night Houston, TX March 27 March 27 Bike Night on the Bay Long Beach, CA March 27 Bike Night at Whiskey River Saloon Port Orange, FL March 27 Bikes & Babes by the Bay Tampa, FL March 27 Back Room Bar & Grill Bike Night New Port Richey, FL March 27 Bike Night At The Back Room Bar & Grill New Port Richey, FL March 27 Century Harley Davidson Garage Party Medina, OH March 27 - 30 The Ultimate Outdoor Experience-San Diego Del Mar, CA March 27 - 30 Thunder in the Hill Country 2014 Bandera, TX March 28 March 28 Back Stage Biker Bash 2014 Arizona Bike Week Mesa, AZ March 28 Chester's H-D Backstage BikerBash Mesa, AZ March 28 Radio Bar and Grill Friday Bikes & Bands Night Tampa, FL & LIVE ONLINE March 28 Indoor Bike Night at Frieze Harley Davidson O'Fallon, IL March 28 Bike Night Presented By A Ride For the Wounded Leavenworth, KS March 28 Bedford Lunch Ride Bedford, TX March 28 - 29 Pink Ride/Pink Ball Texarkana, AR March 28 - 29 CMA Seasons of Refreshing Las Vegas, NV March 28 - 29 BBQ Cook-Off for the Cure Carrollton, TX March 28 - 29 Dallas Harley Davidson 12th Anniversary Party Garland, TX March 28 - 29 Demo Days at Dallas Harley Davidson Garland, TX March 28 - 29 All Access 2014 Demo Event Garland, TX March 28 - 29 Zion Harley Davidson Demo Days Washington, UT March 28 - 30 AHRMA Road Racing - NOLA Motorsports Park Avondale, LA March 28 - 30 Texoma ABATE 2nd Annual Steel Horse Rally Bells, TX March 28 - 30 Thunder in the Pines Motorcycle Rally Jacksonville, TX March 28 - Oct 24 Indian Nation: Indian Motorcycles and America Hershey, PA March 29 March 29 Tillman's Ride Chandler, AZ March 29 Speed and Sport National Vintage Trial Series Chrome, CA March 29 Bikers For Barkers Merced, CA March 29 Biggs Bike Contest San Marcos, CA March 29 Wheel in to Gator Harley Cruise In Leesburg, FL March 29 BIN Run 3rd Annual Melbourne, FL March 29 Sun & Fun Annual Run Zellwood, FL March 29 Apopka Music & Bikefest Zellwood, FL March 29 2014 Servant Riders CMA Blessing of the Bikes Dublin, GA March 29 Ride for Dreams Bogart, GA March 29 Bikes, Blues, and BBQ Fundraiser Holly Springs, GA March 29 Benefit Bike Ride And Chicken BBQ Monroe, GA March 29 Monster Energy AMA Supercross St Louis, MO March 29 Crimson Crusaders Fundraiser BBQ Boiling Springs, NC March 29 Stunt X Showdown Garner, NC March 29 Laconia Harley Davidson Ladies Night Meredith, NH March 29 US Military Vets MC NH Annual Chapter Party Seabrook, NH March 29 Cabin Fever Party 9th Annual Fort Ann, NY March 29 LIC Chicken Wing Eating Contest Long Island City, NY March 29 Harley Davidson Demo Day Greenville, SC March 29 Dallas Motorcycle Swap Meet Allen, TX March 29 Montague County Relay for Life Poker Run Saint Jo, TX March 29 Flying Tigers Bike/Car Show Spring, TX March 29 Blessing of the Bikes Portsmouth, VA March 29 Spring Thaw Open House Roanoke, VA March 29 Open House at Rice Lake Harley Davidson Rice Lake, WI March 29 - 30 Nuclear Cowboyz Freestyle Tour San Jose, CA March 29 - 30 Cajun Blowout Harley Rally and Drags Erwinville, LA March 29 - 30 Donnie Smith Bike Show and Parts Extravaganza 27th Annual St Paul, MN March 29 - 30 WERA Sportsman Series - LVMS Classic Course Las Vegas, NV March 29 - 30 AMA Arenacross Series Salt Lake City, UT March 29 - 30 Demo Days at Shenandoah Harley Davidson Staunton, VA March 30 March 30 AHRMA Vintage Motocross - Borrows Ranch Chrome, CA March 30 Connecticut Spring Motorcycle Swap Meet Stafford Springs, CT March 30 Relay For Life Poker Run Debary, FL March 30 Southwest Florida Tour de Cure 2014 Lakewood Ranch, FL March 30 Sunday is All Day Bike Day at Peggys Corral Palmetto, FL March 30 Screwie Louie's Porpoise Pub's BIKER SUNDAYS Seminole, FL March 30 Beauty Beyond the Pain Ride Augusta, GA March 30 Dealer Ride Woodstock, IL March 30 Oklahoma Motorcycle Swap Meet Oklahoma City, OK March 30 5th Annual Bike and Rider Blessing Kennett Square, PA

Here is a list of motorcycle rallies, rides and events going on throughout the US (there are some Canadian rides listed, as well, though it's not as comprehensive as the U.S. listing. Please feel free to drop a note to me through the blog with any additions. March 1 March 1 Big Swamp Harley Davidson Boot Clinic Opelika, AL March 1 Hot Winter Nights Benton, AR March 1 American Legion Riders Post 61s Shoot n Ride Avondale, AZ March 1 Ride Against Lyme - Benefit Motorcycle Ride and Car Run Peoria, AZ March 1 Crazy Earls Red and White Support Run Yuma, AZ March 1 West Side Show and Shine Modesto, CA March 1 Breast Cancer Run for Randy San Diego, CA March 1 Iron Steed Motorcycle Cleaning Workshop Vacaville, CA March 1 Victory Demo Days Brea, CA March 1 Service Seminar at High Country Harley Davidson Frederick, CO March 1 Michael Mickey McGinley 5th Annual Poker Run Panama City, FL March 1 Riding Gear Essentials Workshop Panama City Beach, FL March 1 Memorial Ride Port Charlotte, FL March 1 Honor Flight Poker Run and Pre Daytona Biker Bash 1st Annual Venice, FL March 1 Volusia County Biker Rights Rally Daytona Beach, FL March 1 1st Annual Honor Flight Poker Run and Pre-Daytona Biker Bash Venice, FL March 1 Barney's 7th Annual Summer Kickoff Parts Unlimited - Tampa, FL March 1 Pre Bike Week Party Clermont, FL March 1 Pre-Heating Bike Week Haines City, FL March 1 Iron Pigs MC - St. Johns River Chapter Monthly Meeting Orlando, FL March 1 ALR Post 129 Bike Night - Jacksonville Beach, FL March 1 Bike Night Pam & Phil @ Extreme Sports Park Clermont, FL March 1 Bikini Bike Wash and Pre-Daytona Bike Week Party Kissimmee, FL March 1 Sleepy Hollow Biker Day Floral City, FL March 1 Hot Rodz and Harleys Columbus, GA March 1 Chattahoochee Harley Davidson Eyewear Clinic Columbus, GA March 1 NE Georgia Swap Meet Commerce, GA March 1 Ride For Randall Baldree Locust Grove, GA March 1 Monster Energy AMA Supercross Indianapolis, IN March 1 Rolling Thunder KY Ch 2 Chili Supper and Live Auction Glasgow, KY March 1 AHRMA Vintage Motocross - Desoto Motorsport Park Grand Cane, LA March 1 New Rider Boot Camp Raleigh, NC March 1 MDA Black and Blue Ball 7th Annual Philadelphia PA March 1 Demo Day at Harley Davidson of Greenville Greenville, SC March 1 Blessing of the Bikes Charleston SC March 1 Texas Independence Day Party College Station, TX March 1 Spring Rally Kick Off Party Houston, TX March 1 Patriot University Tire Service Seminar Fairfax, VA March 1 Ladies of Harley Jambalaya Cook-Off Portsmouth, VA March 1 LOH Jambalaya Cook-Off Portsmouth, VA March 1 Euro Moto Motorcycle Show Lynnwood, WA March 1 - 2 Penton Racing Products National Cross Grand Cane, LA March 1 - 2 Nuclear Cowboyz Freestyle Tour East Rutherford, NJ March 1 - 2 AMA Arenacross Series Tulsa, OK March 1 - 4 Guinness World Record Mini Bike Attempt Clarksville, TN March 2 March 2 Biker Breakfast National City, CA March 2 Sunday is All Day Bike Day at Peggys Corral Palmetto, FL March 2 Screwie Louie's Porpoise Pub's BIKER SUNDAYS Seminole, FL March 2 Webster Westside Swap Meet & Show Webster, FL March 2 Bike Night Pam @ Tijuana Flats Leesburg, FL March 2 Charlotte's Webb Biker Day Wauchula, FL March 2 Sleepy Hollow Biker Day Floral City, FL March 2 Dirty Harrys 1st Sunday BBQ Daytona Beach, FL March 2 Boone County Vintage Metric Motorcycle and Scooter Swap Meet and Auction Lebanon, IN March 2 AHRMA Post Vintage MX - Desoto Motorsport Park Grand Cane, LA March 2 Faribault Harley Davidson HOG Garage Party Faribault, MN March 2 Jeff Williams Motorcycle Swap Meet Sedalia, MO March 2 Sunday Biker Pancake Breakfast Tigard, OR March 3 March 3 M.N.O. Monday @ Porpoise Pub - Musicians Night Off / Monday Night Out! - Seminole, FL March 4 March 4 San Diego Bike Night San Diego, CA March 4 Big Papa's Pit Bike Night Tampa, FL March 4 Bike Night Pam & Phil @ The Bar Ocoee, FL March 4 Screwie Louie's Fat Tuesday Party Cajun Music, Food, & Fun! - Seminole, FL March 4 Venom2 Bike Night - Hudson, FL March 4 Iron Cross Motorcycles Bike Night West Palm Beach, FL March 4 Texoma Harley Davidson Womens Garage Party Sherman, TX March 5 March 5 Ride to Doolittles in Cuba City, Wisconsin Dubuque, IA March 5 Illinois Harley Davidson Service Seminar Countryside, IL March 5 Bike Night Pam @ Beef O'Brady's Clermont, FL March 5 Big Dawg 3 Bike Night Davie, FL March 5 Olde Fish House Marina Matlacha, FL March 5 Popeyes Bike Night LaBelle, FL March 5 Raccoons Bike Night Valrico, FL March 5 Rudy's Crossroads Bike Night Deland, FL March 5 - March 9 The Ultimate Outdoor Experience-Long Beach Long Beach, CA March 6 March 6 Glendale Harley Davidson Ladies Garage Party Glendale, CA March 6 Bike Night on the Bay Long Beach, CA March 6 Motorcycle Boot Camp Aurora, CO March 6 Manatee River Bike Night Bradenton, FL March 6 Black Widow Bike Night Port Charlotte, FL March 6 Bike Night at Whiskey River Saloon Port Orange, FL March 6 Renegades Bar and Grill Bike Night West Palm Beach, FL March 6 Bike Night Pam @ Buffalo Wild Wings Clermont, FL March 6 Back Room Bar & Grill Bike Night New Port Richey, FL March 6 Bike Night At The Back Room Bar & Grill New Port Richey, FL March 6 Ladies Only Garage Party Charleston, SC March 6 - 9 Stock Law Gap Rally Georgiana, AL March 6 - 17 Waterfront Sportsman Rally Point for Daytona Bike Week Mebane, NC March 7 March 7 Motorcycle Boot Camp San Diego, CA March 7 36th Annual Daytona Bikeweek Swapmeet Daytona Beach, FL March 7 Bike Night with Phil @ VFW Winter Garden, FL March 7 Bike Week 2014 ABATE Campground Deland, FL March 7 AMVETS 44 Riders Big Azz Steak Dinner Plant City, FL March 7 Bike Night Pam @ Rock Springs Bar and Grill Apopka, FL March 7 BIKE NIGHT EVERY 1ST AND 3RD FRIDAY Gibsonton, FL March 7 Bike Week Trifecta Inlet Harbor Restaurant - Ponce Inlet, FL March 7 Radio Bar and Grill Friday Bikes & Bands Night Tampa, FL & LIVE ONLINE March 7 Screwie Louie's Bike Week KickOff - Best Buns Contest! w/ ZigZag Seminole, FL March 7 Cacklebery Campground Bike Week New Smyrna Beach, FL March 7 Daytona Bike Week Daytona, FL March 7 Bike Night at Baymeadows Jacksonville, FL March 7 Motorcycle Ride for Lunch Bedford, TX March 7 Mardi Gras Bike Nite Carrollton, TX March 7 - 8 Sunshine National Swap Meet New Smyrna Beach, FL March 7 - 9 Ride for the Warrior III Casa Grande, AZ March 7 - 9 International Vintage Motorcycle Meet and Bike Show 3rd Annual Eustis, FL March 7 - 9 AMA Arenacross Series Albuquerque, NM March 7 - 11 Orlando Harley Davidson Demo Days Kissimmee, FL March 8 March 8 Advanced Motorcycle Skills Training Trussville, AL March 8 Hogs N Dogs Bellemont, AZ March 8 Hogs N Dogs Mayer, AZ March 8 McCarthy Building Companies 2014 Ride for Sight Mesa, AZ March 8 McCarthy Building Companies 2014 Charity Ride Ride For Sight Mesa, AZ March 8 Barger Performance Workshop Canoga Park, CA March 8 Jamestown Swap Meet 18th Annual Jamestown, CA March 8 Fried Chicken Cook Off Lathrop, CA March 8 Bullet Memorial Run San Diego, CA March 8 Womens Harley Davidson Garage Party San Marcos, CA March 8 Port Stockton Motorcycle Club Gold Rush Run - 35th Annual Stockton, CA March 8 Mile High Harley Davidson Performance Workshop Aurora, CO March 8 Orlando Bike Week 2014 Orlando, FL March 8 Suncoast Brotherhood HOWL AT THE MOON POKER RUN Dunedin, FL March 8 Daytona Supercross - Daytona Bike Week Daytona Beach, FL March 8 Shovelhead Bike Show - Daytona Bike Week Deland, FL March 8 Bike Week Kick-Off Car and Bike Show - Daytona Bike Week Palm Bay, FL March 8 Freedom Ride Poker Run and Bike Show Venice, FL March 8 Ellie Lee & The Blues Fury Live @ The Porpoise Pub Seminole, FL March 8 Cacklebery Campground Bike Week New Smyrna Beach, FL March 8 Daytona Bike Week Daytona, FL March 8 Ocala Motorcycle & Car Swap Meet Ocala, FL March 8 ASRA Team Challenge Series - Roebling Road Raceway Bloomingdale, GA March 8 Daytona Pit Stop Party Tifton, GA March 8 Chilly Chaps Ride Meridian, ID March 8 Mardi Gras Party Meridian, ID March 8 Northern Illinois ABATE Cabin Fever Party & Membership Drive Lake Villa, IL March 8 Alefs Harley-Davidson Tips with the Techs Workshop Wichita, KS March 8 Alefs Tips with the Techs - Bike Detailing Workshop Wichita, KS March 8 Kingsman MC Annual Screw Daytona Party Shady Side, MD March 8 Chili Cook-Off St Joseph, MO March 8 St Joe Harley Davidson Service Seminar St Joseph, MO March 8 Kawasaki Customer Appreciation Day Raleigh, NC March 8 Daytona Bike Week Kick-Off Party Meredith, NH March 8 Breakfast Behind Bars Oklahoma City, OK March 8 Harley Davidson Demo Day Greenville, SC March 8 Law Riders MC Oyster Roast 18th Annual Ladson, SC March 8 Dallas Harley-Davidson Clinic: Boom! Audio Workshop Garland, TX March 8 - 9 Parts Unlimited Mud Mucker GNCC Bunnell, FL March 8 - 9 Nuclear Cowboyz Freestyle Tour Orlando, FL March 8 - 9 ASRA Sprint Series - Roebling Road Raceway Bloomingdale, GA March 8 - 9 Wilmington Northeast Motorcycle Expo Wilmington, MA March 8 - 17 The Black Cloud Saloon - Daytona Bike Week 2014 Bunnell, FL March 9 March 9 Hawg Heaven Church Service National City, CA March 9 Free Sober Hog Roast and Live Music - Daytona Bike Week Bunnell, FL March 9 Sunday is All Day Bike Day at Peggys Corral Palmetto, FL March 9 Screwie Louie's Porpoise Pub's BIKER SUNDAYS Seminole, FL March 9 6th Annual Bahia Shrine Sam Swope Charity Ride ORLANDO, FL March 9 Orlando Bike Week 2014 Orlando, FL March 9 Women Blessing Women - Annual Bike Blessing Edgewater, FL March 9 Cacklebery Campground Bike Week New Smyrna Beach, FL March 9 Daytona Bike Week Daytona, FL March 9 The Roast of Victor w/ WAYLAND LIVE @ Screwie Louie's Porpoise Pub Seminole, FL March 9 Rat Bike Show - Daytona Bike Week Deland, FL March 9 Bike Week Chicken Fest - Daytona Bike Week 2014 Deland, FL March 9 Sam Swope Charity Ride for Shriners Hospitals - 6th Annual Orlando, FL March 9 All Rod Show 1st Annual Palm Bay, FL March 9 St Pattys Day Poker Run Benefitting Humane Society of Sarasota County Sarasota, FL March 9 AHRMA Dirt Track Racing - Oglethorpe Speedway Park Pooler, GA March 9 March Madness Last Chance before Spring Swap Meet Boone, IA March 9 GIANT Motorcycle Swap Meet Grand Rapids, MI March 10 March 10 Orlando Bike Week 2014 Orlando, FL March 10 Cacklebery Campground Bike Week New Smyrna Beach, FL March 11 March 11 High Country Motorcycle Boot Camp Frederick, CO March 11 Womens Garage Party at Texas Harley Davidson Bedford, TX March 11 Orlando Bike Week 2014 - Orlando, FL March 11 Screwie Louie's Porpoise Pub - All You Can Eat Shrimp & Crawfish Night! Seminole, FL March 11 Venom2 Bike Night Hudson, FL March 11 Cacklebery Campground Bike Week New Smyrna Beach, FL March 12 March 12 Ditch Work Ride Fresno, CA March 12 Orlando Bike Week 2014 Orlando, FL March 12 Big Dawg 3 Bike Night Davie, FL March 12 Olde Fish House Marina Matlacha, FL March 12 Raccoons Bike Night Valrico, FL March 12 Rudy's Crossroads Bike Night Deland, FL March 12 Cacklebery Campground Bike Week New Smyrna Beach, FL March 12 Daytona Bike Week Daytona, FL March 12 Heart Strings for Heroes Honors Fest Daytona Beach, FL March 12 Side Car and Trike Show - Daytona Bike Week Deland, FL March 12 Fort Myers Harley Davidson Ladies Garage Party Fort Myers, FL March 12 Biker Day at The Capitol 11th Annual St Paul, MN March 12 Greenville Bike Night Greenville, SC March 12 Roanoke Valley Harley Davidson Womens Garage Party Roanoke, VA March 13 March 13 Bike Night on the Bay Long Beach, CA March 13 Bike Night at Whiskey River Saloon Port Orange, FL March 13 Orlando Bike Week 2014 Orlando, FL March 13 Applebee's Bike Night Sarasota, FL March 13 Back Room Bar & Grill Bike Night New Port Richey, FL March 13 Bike Night At The Back Room Bar & Grill New Port Richey, FL March 13 Cacklebery Campground Bike Week New Smyrna Beach, FL March 13 Daytona Bike Week Daytona, FL March 13 Heart Strings for Heroes Honors Fest Daytona Beach, FL March 13 AHRMA Dirt Track Racing - Marion County Speeday Ocala, FL March 13 Motorcycle Boot Camp Columbia, MO March 13 - 15 Norman Swap Meet Norman, OK March 14 March 14 Riders Bike Night Trussville, AL March 14 Orlando Bike Week 2014 Orlando, FL March 14 Radio Bar and Grill Friday Bikes & Bands Night Tampa, FL & LIVE ONLINE March 14 Cacklebery Campground Bike Week New Smyrna Beach, FL March 14 Daytona Bike Week Daytona, FL March 14 Heart Strings for Heroes Honors Fest Daytona Beach, FL March 14 Motorcycle Boot Camp Fort Ann, NY March 14 Texas Harley Lunch Ride Bedford, TX March 14 Spring Dyno Shoot-Out/March Madness Portsmouth, VA March 14 - 16 Wild Wild West Bike Fest Winchester, CA March 14 - 16 WERA National Challenge Series - Roebling Road Raceway Bloomingdale, GA March 14 - 16 WERA Sportsman Series - Roebling Road Raceway Bloomingdale, GA March 14 - 16 Piston Power Show Cleveland, OH March 14 - 16 AMA Arenacross Series Hidalgo, TX March 14 - 16 March Madness/Spring Dyno Shoot Out Portsmouth, VA March 14 - 16 Inland Northwest Motorcycle Show Spokane, WA March 15 March 15 Preventitive Motorcycle Maintenance Clinic Opelika, AL March 15 Riders Harley Open House Trussville, AL March 15 Natchez Trace HD 2nd Annual Saint Patty's Party Tuscumbia, AL March 15 Saint Patty Party Fort Smith, AR March 15 Chester's Harley-Davidson Party on the Patio Mesa, AZ March 15 Annual Bike Blessing Mayer, AZ March 15 Mesa Police Department Motor Unit Escorted Ride Mesa, AZ March 15 Chili Cook Off 6th Annual San Diego, CA March 15 Luck of the Irish Poker Ride 3rd Annual San Marcos, CA March 15 Lords Prospects Motorcycle Ministry Bike Blessing Vacaville, CA March 15 St Pattys Day Ride Vacaville, CA March 15 24th Annual Super Show & Swap Meet Colorado Springs, CO March 15 Heart Strings for Heroes Canopy of Cards Poker Run Daytona Beach, FL March 15 Orlando Bike Week 2014 Orlando, FL March 15 Cacklebery Campground Bike Week New Smyrna Beach, FL March 15 Fox and Hounds Bike Night St. Patty's Day Weekend Party Brandon, FL March 15 Antique Bike Show Deland, FL March 15 Crimeline BBQ Cook-Off Palm Bay, FL March 15 Empty Canteen Poker Run and Scavenger Hunt - 6th Annual Acworth,GA March 15 Kelsi Long Memorial Ride Augusta, GA March 15 Riding Gear Essentials Workshop Bogart, GA March 15 Pink Ladies for Breast Cancer Awareness Columbus, GA March 15 St Patricks Day Party and Bike Show at MCHD Dalton, GA March 15 Open House at Woodstock Harley Davidson Woodstock, IL March 15 Alefs St Patty's Event Wichita, KS March 15 Sergeant Audie Murphy Club (SAMC) Poker Run Leesville, LA March 15 Nuclear Cowboyz Freestyle Tour New Orleans, LA March 15 Monster Energy AMA Supercross Detroit, MI March 15 Spring Open House at Faribault Harley Davidson Faribault, MN March 15 Ride With The King Motorcycle Ride and Rally Tupelo, MS March 15 Durham HOG 28th Annual Bike Show and Chili Cookoff Durham, NC March 15 New York City Harley Davidson St Patrick's Day Event Manhattan, NY March 15 St Patricks Day Party North Tonawanda, NY March 15 Summer Ride Series Kickoff Harrisburg, PA March 15 Harley Davidson of Greenville Demo Days Greenville, SC March 15 St Patricks Day Party and Bike show Chattanooga, TN March 15 Cowboy Harley Davidson Lot Party Beaumont, TX March 15 Snap-on Masters of Metal Tour Garland, TX March 15 St Patty's Day Party Grand Prairie, TX March 15 Texas Thunder Annual Chili Cook-Off Nacogdoches, TX March 15 Bikes and Beads Sherman, TX March 15 Blessing of the Bikes The Woodlands, TX March 15 St Patricks Day Ride Barre, VT March 15 - 16 Super Show and Swap Meet 24th Annual Colorado Springs, CO March 15 - 16 Penton Racing Products National Cross Country Series Chester, SC March 16 March 16 So Cal - CRUISE IN - Free Event Lake Elsinore, CA March 16 24th Annual Super Show & Swap Meet Colorado Springs, CO March 16 Colorado Tattoo Competition 22nd Annual Colorado Springs, CO March 16 Sunday is All Day Bike Day at Peggys Corral Palmetto, FL March 16 Screwie Louie's Porpoise Pub's BIKER SUNDAYS Seminole, FL March 16 Central Florida Motorcycle Swap Meet and Greet Kissimmee, FL March 16 Orlando Bike Week 2014 Orlando, FL March 16 Cacklebery Campground Bike Week New Smyrna Beach, FL March 16 Fox and Hounds Bike Night St. Patty's Day Weekend Party Brandon, FL March 16 Motorcycle Swap Meet St. Augustine, FL March 16 41st Annual Kalamazoo Swap Meet Kalamazoo, MI March 16 Faribault Harley Davidson Ladies Garage Party Faribault, MN March 16 Rides of March New Rochelle, NY March 16 St Patty's Day Ride Franklin, TN March 16 ABATE Region 2E 15th Annual Motorcycle Show and Swap Meet Menasha, WI March 17 March 17 Screwie Louie's St. Patty's Day Bash at the Porpoise Pub Seminole, FL March 17 Fox and Hounds Bike Night St. Patty's Day Weekend Party Brandon, FL March 18 March 18 Big Papa's Pit Bike Night Tampa, FL March 18 Venom2 Bike Night Hudson, FL March 19 March 19 High Country Harley Davidson Garage Party Frederick, CO March 19 Raccoons Bike Night Valrico, FL March 19 Rudy's Crossroads Bike Night Deland, FL March 19 Ride to Sharks in Elizabeth, Illinois Dubuque, IA March 19 High Desert Harley Davidson Garage Party Meridian, ID March 19 Alefs Harley Davidson Womens Garage Party Wichita, KS March 19 Bike Night at Harley Davidson of Greenville Greenville, SC March 20 March 20 Mobile Bay Bike Night Mobile, AL March 20 Bike Night on the Bay Long Beach, CA March 20 Mile High Harley Davidson Ladies Garage Party Aurora, CO March 20 Bike Night at Harley Davidson of Palm Beach West Palm Beach, FL March 20 Bike Night at Whiskey River Saloon Port Orange, FL March 20 Bike Night At The Back Room Bar & Grill New Port Richey, FL March 20 City Limits Harley Davidson Motorcyle Service Seminar Palatine, IL March 20 Woodstock Harley Davidson Garage Party Woodstock, IL March 20 Barb's Harley Davidson Womens Garage Party Mt. Ephraim, NJ March 20 Custom Bike Unveiling Long Island City, NY March 20 Bike Night at Jimbos Roadhouse Hockley, TX March 20 Screw Winter Party Barre, VT March 20 - 23 Bama Bike Fest Spring Motorcycle Rally Forkland, AL March 21 March 21 BIKE NIGHT EVERY 1ST AND 3RD FRIDAY Gibsonton, FL March 21 Radio Bar and Grill Friday Bikes & Bands Night Tampa, FL & LIVE ONLINE March 21 Bike Night Presented By A Ride For the Wounded Leavenworth, KS March 21 Texas Harley Davidson Lunch Ride Bedford, TX March 21 - 23 Spring Swap Meet, Bike/Car Show, and BBQ Cookoff Springfield, GA March 21 - 23 Iron Horse Bike Show Grand Island, NE March 22 March 22 Wheels for Wilmer Hall - 2nd Annual Mobile, AL March 22 Helping Honduras Ride Opelika, AL March 22 Habitat for Humanity Central Arizona Show and Shine for Shelter Car and Motorcycle Show 2nd Annual Apache Junction, AZ March 22 American Legion Riders Chapter 58 Bike and Hot Rod Show 5th Annual Fountain Hills, AZ March 22 Biggs Breakfast and Crew Ride San Marcos, CA March 22 American Legion Post 53 Poker Run Temecula, CA March 22 AHRMA Vintage Motocross - Motocross of Marion County Citra, FL March 22 AMSTAR Spangled Heroes Poker Run and Fund Raiser TRACK CHAIR INITIATIVE - Crystal River, FL March 22 LED Lighting Workshop Fort Myers, FL March 22 Place Tavern Biker Bash and Party Punta Gorda, FL March 22 Seminole Swap Meet Sanford, FL March 22 Music and Motorcycles Zephyrhills, FL March 22 Spring Thaw Countryside, IL March 22 Alefs Tips with the Techs - LED Wichita, KS March 22 Alefs Harley-Davidson Tips with the Techs Workshop Wichita, KS March 22 Clay Humane's Hogs for Dogs Bike Run - Orange Park, FL March 22 Spring Breakout 2nd Annual Marquette, MI March 22 Service Seminar at St Joe Harley Davidson St Joseph, MO March 22 Orphan Run High Point, NC March 22 Young Marines Poker Run Raleigh, NC March 22 Monadnock Harley Davidson Spring Open House Swanzey, NH March 22 Spring Fever Run Oklahoma City, OK March 22 Monster Energy AMA Supercross Toronto, ON CAN March 22 Open House at Timms Harley Davidson Anderson, SC March 22 Demo Day at Harley Davidson of Greenville Greenville, SC March 22 Harley Davidson of Dallas Demo Day Allen, TX March 22 The Breath of Life Biker Ball Springville, UT March 22 Dealer Ride NRV to Amelias Roanoke, VA March 22 - 23 Custom Motorcycle Show and Expo Mount Clemens, MI March 22 - 23 CMRA Road Racing - Texas World Speedway College Station, TX March 23 March 23 So-Cal Cycle Swap Meet Long Beach, CA March 23 AHRMA Post Vintage MX - Motocross of Marion County Citra, FL March 23 Forgotten Soldiers Outreach Poker Run Greenacres, FL March 23 Sunday is All Day Bike Day at Peggy's Corral Palmetto, FL March 23 Screwie Louie's Porpoise Pub's BIKER SUNDAYS Seminole, FL March 23 Cycle World Customer Appreciation Bogart, GA March 23 Walneck Motorcycle Swap Meet and Show St Charles, IL March 23 Pancake Breakfast Forked River, NJ March 23 GIANT Motorcycle Swap Meet Berea, OH March 23 Harrisburg Super Swap Meet Harrisburg, PA March 23 Coyote Motorcycle Swap Meet Fort Worth, TX March 24 March 24 Mathews Harley Motorcycle Boot Camp Fresno CA March 25 March 25 Venom2 Bike Night Hudson, FL March 26 March 26 Ditch Work Ride Fresno, CA March 26 High Country Harley Davidson Garage Party Frederick, CO March 26 Raccoons Bike Night Valrico, FL March 26 Rudy's Crossroads Bike Night Deland, FL March 26 Motorcycle Boot Camp Long Island City, NY March 26 American Harley Davidson Womens Garage Party North Tonawanda, NY March 26 South Carolina Bike Night Greenville, SC March 26 Motorcycle Boot Camp Garland, TX March 26 Bike and Steak Night Houston, TX March 27 March 27 Bike Night on the Bay Long Beach, CA March 27 Bike Night at Whiskey River Saloon Port Orange, FL March 27 Bikes & Babes by the Bay Tampa, FL March 27 Back Room Bar & Grill Bike Night New Port Richey, FL March 27 Bike Night At The Back Room Bar & Grill New Port Richey, FL March 27 Century Harley Davidson Garage Party Medina, OH March 27 - 30 The Ultimate Outdoor Experience-San Diego Del Mar, CA March 27 - 30 Thunder in the Hill Country 2014 Bandera, TX March 28 March 28 Back Stage Biker Bash 2014 Arizona Bike Week Mesa, AZ March 28 Chester's H-D Backstage BikerBash Mesa, AZ March 28 Radio Bar and Grill Friday Bikes & Bands Night Tampa, FL & LIVE ONLINE March 28 Indoor Bike Night at Frieze Harley Davidson O'Fallon, IL March 28 Bike Night Presented By A Ride For the Wounded Leavenworth, KS March 28 Bedford Lunch Ride Bedford, TX March 28 - 29 Pink Ride/Pink Ball Texarkana, AR March 28 - 29 CMA Seasons of Refreshing Las Vegas, NV March 28 - 29 BBQ Cook-Off for the Cure Carrollton, TX March 28 - 29 Dallas Harley Davidson 12th Anniversary Party Garland, TX March 28 - 29 Demo Days at Dallas Harley Davidson Garland, TX March 28 - 29 All Access 2014 Demo Event Garland, TX March 28 - 29 Zion Harley Davidson Demo Days Washington, UT March 28 - 30 AHRMA Road Racing - NOLA Motorsports Park Avondale, LA March 28 - 30 Texoma ABATE 2nd Annual Steel Horse Rally Bells, TX March 28 - 30 Thunder in the Pines Motorcycle Rally Jacksonville, TX March 28 - Oct 24 Indian Nation: Indian Motorcycles and America Hershey, PA March 29 March 29 Tillman's Ride Chandler, AZ March 29 Speed and Sport National Vintage Trial Series Chrome, CA March 29 Bikers For Barkers Merced, CA March 29 Biggs Bike Contest San Marcos, CA March 29 Wheel in to Gator Harley Cruise In Leesburg, FL March 29 BIN Run 3rd Annual Melbourne, FL March 29 Sun & Fun Annual Run Zellwood, FL March 29 Apopka Music & Bikefest Zellwood, FL March 29 2014 Servant Riders CMA Blessing of the Bikes Dublin, GA March 29 Ride for Dreams Bogart, GA March 29 Bikes, Blues, and BBQ Fundraiser Holly Springs, GA March 29 Benefit Bike Ride And Chicken BBQ Monroe, GA March 29 Monster Energy AMA Supercross St Louis, MO March 29 Crimson Crusaders Fundraiser BBQ Boiling Springs, NC March 29 Stunt X Showdown Garner, NC March 29 Laconia Harley Davidson Ladies Night Meredith, NH March 29 US Military Vets MC NH Annual Chapter Party Seabrook, NH March 29 Cabin Fever Party 9th Annual Fort Ann, NY March 29 LIC Chicken Wing Eating Contest Long Island City, NY March 29 Harley Davidson Demo Day Greenville, SC March 29 Dallas Motorcycle Swap Meet Allen, TX March 29 Montague County Relay for Life Poker Run Saint Jo, TX March 29 Flying Tigers Bike/Car Show Spring, TX March 29 Blessing of the Bikes Portsmouth, VA March 29 Spring Thaw Open House Roanoke, VA March 29 Open House at Rice Lake Harley Davidson Rice Lake, WI March 29 - 30 Nuclear Cowboyz Freestyle Tour San Jose, CA March 29 - 30 Cajun Blowout Harley Rally and Drags Erwinville, LA March 29 - 30 Donnie Smith Bike Show and Parts Extravaganza 27th Annual St Paul, MN March 29 - 30 WERA Sportsman Series - LVMS Classic Course Las Vegas, NV March 29 - 30 AMA Arenacross Series Salt Lake City, UT March 29 - 30 Demo Days at Shenandoah Harley Davidson Staunton, VA March 30 March 30 AHRMA Vintage Motocross - Borrows Ranch Chrome, CA March 30 Connecticut Spring Motorcycle Swap Meet Stafford Springs, CT March 30 Relay For Life Poker Run Debary, FL March 30 Southwest Florida Tour de Cure 2014 Lakewood Ranch, FL March 30 Sunday is All Day Bike Day at Peggys Corral Palmetto, FL March 30 Screwie Louie's Porpoise Pub's BIKER SUNDAYS Seminole, FL March 30 Beauty Beyond the Pain Ride Augusta, GA March 30 Dealer Ride Woodstock, IL March 30 Oklahoma Motorcycle Swap Meet Oklahoma City, OK March 30 5th Annual Bike and Rider Blessing Kennett Square, PADo we have great customers or what? We received another really nice review of the PRO 1200 Motorcycle Lift from Joe in Canada. Thanks Joe, for taking the time to leave this review. We really appreciate the feedback and we're so glad to hear you are happy with your purchase! "I build a couple bikes a year. This lift is more than I expected for the price, and is built very well . Clark was a pleasure to deal with and will definitely get more of my business." We've been shipping to Canada for some time now, and we are always happy to quote shipping rates for those of you north of the border! Please call Clark at 603-234-2612 for detail.

This Thermadyne FirePower MIG Welder is currently in stock! CALL CLARK @ 603-234-2612 OR VISIT STORE @ 678 RTE 3A BOW, NH - NO NH SALES TAX! The FP260 MIG Welding System offers industrial performance at an affordable price. This system includes the most popular features desired by professional welders and increases efficiency and productivity. This unit is ideal for fabrication work, garage/auto body, fleet, farm and ranch repairs. The perfect choice for the serious welder. The FP260 dual purpose MIG Welding System features quick change internal polarity adjustment that makes changing from MIG (GMAW) to Flux Cored (FCAW) welding processes quick and easy. FEATURES Welds 22 gauge to 5/8" mild steel in a single pass Excellent aluminum capabilities with optional spool gun Euro style easy connect MIG gun system Spool gun ready Heavy duty gear driven wire feed system Seven position welding power output control Spot weld timer Adjustable burn back control Adjustable soft arc control Infinite wire speed control Heavy duty braking system Built-in cylinder rack and running gear Illuminated power on indicator Illuminated thermal over load warning indicator 2 pound, 10 pound, 30 pound wire spool capacity Thermostatic overload protection 5-2-1 Warranty Comes Complete With Genuine Firepower® argon regulator 10 foot genuine Tweco MIG gun 10 foot ground cable and work clamp 6 foot power cord (without plug) Welding nozzle and tip Spool of .035 MIG welding wire Instruction manual (English, French, Spanish) Input Voltage: 230 volt 60 HZ Input Current Amps: 35 Welding Output Voltage: 26 Maximum Output Amps: 270 Open Circuit Voltage: 43 Rated Output Amps: 200 Rated Duty Cycle: 60 percent Maximum Thickness Capacity: 5/8 inches Wire Feed Speed: 98 through 905 IPM Dimensions: 31 x 19 1/2 x 33 inches (785 mm x 488 mm x 840 mm) Weight: 200 pounds (91kg)

This Thermadyne FirePower MIG Welder is currently in stock! CALL CLARK @ 603-234-2612 OR VISIT STORE @ 678 RTE 3A BOW, NH - NO NH SALES TAX! The FP260 MIG Welding System offers industrial performance at an affordable price. This system includes the most popular features desired by professional welders and increases efficiency and productivity. This unit is ideal for fabrication work, garage/auto body, fleet, farm and ranch repairs. The perfect choice for the serious welder. The FP260 dual purpose MIG Welding System features quick change internal polarity adjustment that makes changing from MIG (GMAW) to Flux Cored (FCAW) welding processes quick and easy. FEATURES Welds 22 gauge to 5/8" mild steel in a single pass Excellent aluminum capabilities with optional spool gun Euro style easy connect MIG gun system Spool gun ready Heavy duty gear driven wire feed system Seven position welding power output control Spot weld timer Adjustable burn back control Adjustable soft arc control Infinite wire speed control Heavy duty braking system Built-in cylinder rack and running gear Illuminated power on indicator Illuminated thermal over load warning indicator 2 pound, 10 pound, 30 pound wire spool capacity Thermostatic overload protection 5-2-1 Warranty Comes Complete With Genuine Firepower® argon regulator 10 foot genuine Tweco MIG gun 10 foot ground cable and work clamp 6 foot power cord (without plug) Welding nozzle and tip Spool of .035 MIG welding wire Instruction manual (English, French, Spanish) Input Voltage: 230 volt 60 HZ Input Current Amps: 35 Welding Output Voltage: 26 Maximum Output Amps: 270 Open Circuit Voltage: 43 Rated Output Amps: 200 Rated Duty Cycle: 60 percent Maximum Thickness Capacity: 5/8 inches Wire Feed Speed: 98 through 905 IPM Dimensions: 31 x 19 1/2 x 33 inches (785 mm x 488 mm x 840 mm) Weight: 200 pounds (91kg)I periodically post messages on Facebook to ask our awesome customers to let us know what they think of the products they've purchased from us...we like feedback! We want to hear from people! We like to engage them, learn about their needs, and their overall impressions of the products they invest in. I specifically asked folks to let us know what they'd thought of our PRO 1200 motorcycle lift, and if they had anything to share, to reply with a comment to my Facebook status. We also LOVE pictures! Can't get enough photos of the lift in your garage with your bike on it...or...if not a bike, whatever else you may use it for....

Thanks to Josh down in North Carolina for this great photo! We got a good chuckle out of it! While we hope it's an effective motorcycle lift, we also hope it makes for a comfortable bed to a sleepy little one, too!

After taking the month of January off from motorcycle event postings (after all....is there much riding to be done in January, given the cold weather the U.S. has been recently experiencing?), it seemed fitting to get back on the beam for February. There are certainly warmer areas than NH in February in the United States, but I think on the whole the country has experienced some unusually cold spells....even down south! Tough to ride in those conditions.

However... I think we have a pretty good number of entries for February! If you have anything to add, please leave a comment to this blogpost and I will be sure to add it. Please make sure to submit the date of the event, the name of the event, the city and state that the event is being held, and a website for more information, if you have one.

2/1 Ottawa Motorcycle Show Ottawa, CANADA 2/1 2nd Annual Biker Ball Yarmouth, MA

2/1 Easyriders 2014 Nashville Bike Show Nashville, Tennessee 2/1 Osceola Law Ride (Sheriff Escorted) Orlando, Florida

2/1 Animal Rescue Dice Run at Stormy Hill Harley-Davidson Clermont, Florida

2/1 Plant City Bike Fest Plant City, Florida

2/1-2/2 Colorado Motorcycle Expo Denver, Colorado 2/2 Webster Westside Auto & Cycle Swap Meet & Show Webster, Florida

2/2 30th Annual Peotone Illinois Motorcycle Swap Meet Peotone, Illinois

2/7 Hot Winter Nights Cyclemax Wilson, NC

2/7-2/9 Progressive International Motorcycle Shows Chicago, IL

2/7-2/9 St. Valentine’s Day Motorcycle Massacre Hondo, TX 2/8 Happy Days Are Here Again Sanford, Florida

2/8 Hot Winter Night Event! Twigg Cycles Hagerstown, MD 2/8 Iron & Clematis Vintage Motorcycle Festival West Palm Beach, Florida

2/8-2/9 Rockingham Northeast Motorcycle Expo - Salem, New Hampshire

2/8-2/9 Easyriders 2014 Columbus Bike Show Columbus, Ohio

2/9 First Annual Buccaneer Bikers Poker Run Brooksville, Florida

2/9 8th Annual Treasure Coast Bike Fest Stuart, Florida

2/14-2/16 Indiana Motorcycle Expo Indianapolis, Indiana

2/14-2/16 Progressive International Motorcycle Shows Seattle, WA

2/15 GWRRA FL2-G Yellow Jackets Chili Cook-Off Fort Myers, Florida

2/15 Jim's H-D Customer Swap Meet St. Petersburg, Florida

2/15 5th Annual "Party Under The Bridge" Moore Haven, Florida 2/15 Annual Biker's Ball for Alzheimers Winter Haven, Florida

2/15 SCVR's Mid Winter Party/Membership Drive Cottage Grove, Minnesota

2/15 Zanesville Trail Riders Swap Meet & Bike Show Zanesville, Ohio

2/15-2/16 17th Annual Oklahoma Motorcycle & Car Show Oklahoma City, OK

2/15-2/16 29th Annual ABATE-District 1 Swap Meet & Ride in Bike Show Little Rock, Arkansas

2/16 Bikers Soar For Wildlife Peoria, Arizona 2/16 Rumble on 5th Ride Naples, Florida

2/16 24th Annual Motorcycle Swap Meet Brilliant, Ohio

2/16 Mountaineer Casino Motorcycle Swap Meet Chester, West Virginia 2/20 Bike Night West Palm Beach, Florida

2/20 Hot Winter Nights at Village Motorsports Holland, Michigan

2/22 Hot Winter Nights at Niehaus Cycle Sales Litchfield, Illinios

2/21-2/23 Nuclear Cowboyz Freestyle Motocross (FMX) Tour Tampa, Florida

2/22 Red Iron Ride Phoenix, Arizona

2/22 Freedom Fest 2014 Music, Food, Beer, Vendors and More Lakeland, Florida

2/22-2/23 Blackstone Valley Harley Owners Group Foxboro, Massachusetts

2/23 2nd Annual Big Chill Ride Poker Run Melbourne, Florida

The Smokewizard GLD-50 is the lightest, smallest smoke detector on the market, a great value when on a budget. It also features smoke volume (flow) control for easier leak detection. This unit is OEM-Approved. Small and Lightweight: 10″ x 5″ x 8.5″ – under 7 lbs. Visit Smoke Wizard GLD-50 for more details.

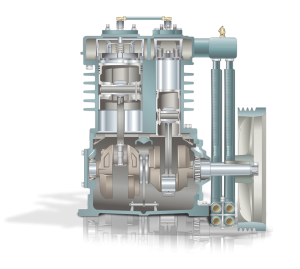

The Smokewizard GLD-50 is the lightest, smallest smoke detector on the market, a great value when on a budget. It also features smoke volume (flow) control for easier leak detection. This unit is OEM-Approved. Small and Lightweight: 10″ x 5″ x 8.5″ – under 7 lbs. Visit Smoke Wizard GLD-50 for more details.Transcript: Matt Smith is at the factory at FS Curtis headquarters in St. Louis, MO, and he has answered a popular question they hear a lot from folks: "Why would I choose a duplex reciprocating air compressor instead of just one bigger air compressor or 2 smaller separately mounted packages?" There are several key reasons you would choose a duplex machine. First off, duplex provides 100% backup. If I'm doing maintenance on one pump, where one pump goes down, I always have the other pump to provide 100% backup and cover all of the air demands of my shop. Second, because rotary screw technology is a great intermittent technology, it is ideal for applications where demand vary widely. So let's take the example of a 20 bay shop. If I have a 20 bay shop, and on the average day I only use 10 of those bays, I wouldn't want to size a rotary screw compressor to cover all 20 of those bays, because rotary screw technology likes to run all the time. If I oversize the rotary screw compressor to cover all 20 bays and run it at only 50% duty cycle the rest of the time, I'm going to run into all kinds of problems with the rotary screw technology. Because recip technology likes to run intermittently, over-sizing a duplex compressor is the ideal solution. We have one pump that can run and cover the 50% of the time that I'm only running 50% of my bays and we have both compressors to cover all 20 bays when the need kicks in to do so. A related benefit of this is that we would save energy costs with the duplex air compressor in this application because on those days when I only run 10 bays, I run one smaller horsepower motor instead of a bigger horsepower motor if I had sized one compressor to cover all of the demand. A related benefit is also pump life in this situation because if I sized one compressor to cover all 20 bays, I would be running one pump whenever I needed air. With a duplex air compressor, you alternate back and forth between pumps so that you share the demand between 2 different pumps and you increase the pump life. Finally, the last reason you would want to use a reciprocating duplex air compressor is space requirements. If you have limited space but you need 2 pumps you can mount 2 pumps on one tank instead of having 2 separately mounted tanks, so duplex is ideal if space requirements are a consideration as well.

M L Series Air Compressor

L Series Air Compressor

Safety Precautions The owner, lessor or operator of any compressor unit manufactured by FS Curtis, Inc. is hereby warned that failure to observe all safety precautions may result in serious injury of personnel and/or damage to property. FS Curtis, Inc. neither states as fact, nor in any way implies that this list of safety precautions is an all-inclusive list, the observance of which will prevent all damage to property or injury to personnel. Every reasonable effort has been taken to ensure that complete and correct instructions have been included in this manual. However, possible updates and changes may have occurred since this printing. FS Curtis,Inc. reserves the right to change specifications, without incurring any obligation for equipment previously or subsequently sold. Compressors and/or units are assembled to comply with the customer’s purchase order and in compliance with FS Curtis, Inc. specifications; alteration must not be made to the compressor or unit without FS Curtis’ written approval.

DANGER! Air used for breathing or food processing must meet O.S.H.A 29 C.F.R. 1910.134 or F.D.A. 21 C.F.R. 178.350 regulations. Failure to do so will cause severe injury or death.

WARNING! Compressors are precision high-speed mechanical equipment requiring caution in operation to minimize hazard to property and personnel. Listed below are some safety precautions that must be observed. Use of Curtis Compressors to transfer toxic, radioactive, flammable, or explosive substances is prohibited. Do not install the compressor in an area where there is a risk of exposure to explosive gases or combustible dusts, such as flours, starches, coke, coal dust, etc. or in close proximity to corrosive substances. Release all air pressure from the system before working on the unit and red tag all electrical control switches. On base mounted units with no receiver tank, the installation of safety valves in the discharge line is the responsibility of the end user. Failure to install safety valves in the discharge line could cause property damage, injury and / or loss of life. Do not operate compressor on a shipping skid or any other unapproved mounting surfaces. Do not by-pass motor over-current protection. Do not change the setting or in any way affect the operation of the safety valves. Turn off and lockout/tagout the main power disconnect switch before attempting to work or perform any maintenance. Do not attempt to service any part of this unit while it is running. Ensure that service personnel are properly grounded before attempting to service any part of the electrical system. Do not operate the unit with any of its safety guards, shields or screens removed. Do not remove or paint over any DANGER!, WARNING!, CAUTION!, or instructional materials attached to the compressor.

Lack of information regarding hazardous conditions can cause property damage or personal injury. Do not change the pressure setting of the pressure relief valve, restrict the function of the pressure relief valve, or replace the pressure relief valve with a plug. Do not install a shutoff valve in the compressor discharge line without first installing a pressure relief valve of proper size and design between the shutoff valve and the compressor.

Do not use plastic pipe, unapproved rubber hose, or lead-tin soldered joints in any part of the compressed air system. Alterations must not be made to this compressor without FS Curtis’ expressed, written approval.

Do not operate the compressor in excess of the A.S.M.E. pressure vessel rating for the receiver or the service rating of the compressor, whichever is lower. Surface temperatures can exceed 400 °F, power off the unit and allow it to cool before touching any surface of the compressor.

Provisions should be made to have the instruction manual readily available to the operator and maintenance personnel. If for any reason any part of the manual becomes illegible or the manual is lost, contact your local distributor. Your State and/or local OSHA regulations may require a Pressure Vessel Permit to operate this equipment. Obtaining a permit is the sole responsibility of the owner, lessor or operator of the equipment. Contact your State/Local OSHA for more information.

FS Curtis manufactures a broad array of compressor configurations to satisfy the needs of our diverse customer base. Despite this diversity, all FS Curtis two stage compressor configurations work off the same basic cycle.

Air is drawn into the compressor through the air intake and filter assembly. The air enters the first stage, a low pressure chamber where it is compressed the first time. As air is compressed, its temperature increases, this hot air then enters the intercooler where the temperature is reduced.

Next, the cooled air enters the second stage, a high pressure chamber where the air is compressed a second time to even higher pressures and discharged into the tank.

An Ultra Pack option can be purchased with an installed air-cooled after-cooler which, after the second compression stage, cools the air to a 20°F approach temperature before being stored in the tank. When the compressor has filled the tank to its pressure rating, the pressure switch disengages which turns off the motor, preventing the tank from over pressurizing. Finally, the tank has a ball valve which is opened or closed by the operator and lets air out of the tank.

Duplex units operate in much the same way as simplex units, only there are two compressors. The key difference is in the pressure switch and starter. In a duplex unit, there are two pressure switches, a “lead” pressure switch and a “lag” pressure switch set 10 psi lower than the lead switch. The alternator utilizes both compressors to fill the tank. Once the tank approaches the cutoff “lag” pressure, the alternator selects one compressor to be the “lag” compressor and cycles it off, using only the “lead” compressor to provide the remaining pressure. The alternator then cycles between both compressors, switching the “lead” and “lag” compressor and ensuring roughly equal wear between them. If air usage exceeds the output of a single compressor, the alternator utilizes both the “lead” and the “lag compressor to fulfill operating conditions, once again cycling off the “lag” compressor when its cutoff pressure is reached. Base mounted Large Industrial compressors are capable of outing large amounts of air at high pressures and come in single stage, two stage, or high pressure varieties. They work off the same basic compressor cycle that tank mounted units operate on.

NOTE: As these units do not come with a receiver tank, the installation of safety valves in the discharge line is the responsibility of the end user.

INSTALLATION IMPORTANT NOTICE Abide by all applicable state, local and regulations when mounting and installing the compressor. Failure to do so may result in injury or death and will void the manufacturer’s warranty. Contact your local government for more information.

CAUTION! Improper lifting can result in component or system damage or personal injury. Follow good shop practices and safety procedures when moving the unit.

Receiving

Immediately upon receipt of compressor equipment and prior to completely uncrating, the following steps should be taken: 1. Inspect compressor equipment for damage that may have occurred during shipment. If any damage is found, demand an inspection from the carrier. Ask the carrier how to file a claim for shipping damages. (Refer to FREIGHT DAMAGE for complete details.) Shipping damage is not covered by FS Curtis’s compressor warranty. 2. Ensure that adequate lifting equipment is available for moving the compressor equipment and clear a path to the installation location to avoid damage to property or compressor. 3. Turn off & lock out the electrical disconnect switch before working on the unit to prevent the unit from starting unexpectedly. 4. Read the compressor nameplate to verify the model and size ordered. 5. Read the motor nameplate to be sure the motor is compatible with your electrical conditions (volts, phase, and hertz). 6. Read the pressure relief valve nameplate to be sure it does not exceed the working pressure of the compressor or any other component in the system. 7. Read and understand the safety precautions contained within this manual. The successful and efficient operation of compressor equipment depends largely upon the amount of care taken to install and maintain the equipment. FS Curtis strongly recommends that any or all person(s) in charge of installing, maintaining, or servicing one of our compressors read and understand the entire contents of this manual and the respective compressor installation and operating instruction manual in order to perform such duties safely and efficiently. 8. Remove all packing plastic, foam and shipping related materials.

FREIGHT DAMAGE

The transportation industry has adopted a modification with regard to the handling of obvious and concealed damage claims. Therefore, it is extremely important that you examine every carton and crate as soon as you receive it. If there is any obvious damage to the shipping container, have the delivering carrier sign the freights bill, noting the apparent damage, and request a damage report. If concealed damage is discovered at a later date, the carrier must be notified within 15 days of initial receipt of freight. Contact the carrier as soon as possible, giving them an opportunity to inspect the shipment at the premises where the original delivery was made. Retain all containers and packing for inspection by the carrier. Do not move the freight. Concealed shipping damage is not covered by the FS-Curtis warranty. A claim form can be requested from the carrier. Your claim will need to be substantiated with the following documents. -Original bill of lading -Original paid freight bill -Original invoice or certified copy -Other particulars obtainable in proof of loss or damage (photos, damage inspection report, etc.) We suggest these instructions be circulated to your shipping and receiving personnel.

Installation Procedure

Step 1 – Select a proper location for installation Select a clean, dry, well lit area with a rigid floor strong enough to support the compressor and with adequate ventilation. Avoid placement of the compressor in an area that is excessively hot, dusty, humid or contaminated with foreign gases such as ammonia or acid fumes. The unit should never be operated at ambient temperatures above 104°F or below 32°F. If the ambient temperature is below 40°F, FS Curtis recommends using Arctic oil. Maintenance checks are required daily, thus three (3) feet of space needs to be provided around the compressor for proper inspection.

Note – If the unit or air intake is to be located outdoors, please contact Clark Heintz Tools & Equipment, LLC, authorized distributor, for additional instructions.

Step 2 – Remove the skid Remove and discard the shipping skid. The compressor should NEVER be operated on a skid.

Step 3 – Prepare the mounting surface If you wish to utilize an installation method other than the approved methods displayed in this manual, please contact Clark Heintz Tools & Equipment, LLC, authorized distributor. FS Curtis neither states as fact, nor implies that the above list of Acceptable/Unacceptable mounting is all-inclusive.

Step 4 – Install Vibration Isolator pads and mount the compressor Exposure to excessive vibrations can significantly shorten the life of the compressor. FS Curtis highly recommends mounting the unit on vibration isolator pads and the compressor should NEVER be operated without being securely fastened to the ground. Using a level, please check for proper alignment of the compressor. Uneven installation will unbalance the compressor leading to excessive noise, vibrations, and wear. Place a steel shim between the concrete and vibration pads and shim down as necessary for leveling. Level the compressor so it can be bolted down securely. Before tightening the bolts, check to see that all four feet are resting on the foundation. See fig (5) for mounting instructions for a floor stud, and see fig (6) for mounting instructions for an anchor bolt. [see diagram] Recommended Installation – Use concrete anchor bolt

Step 5 – Tighten the fasteners Incrementally tighten the mounting bolts evenly in a cross pattern. If necessary, after start up, continue incrementally tightening the mounting bolts in a crossing pattern until vibrations have been reduced to an acceptable level. After vibrations have been minimized, loosen ONE mounting bolt. The unit expands and contracts with changes in temperature, leaving ONE bolt loosened will allow for thermal expansion of the unit, reducing thermal stresses and vibrations on the tank. If after loosening one bolt the vibrations get worse, retighten bolt and select a different unit. Excessive vibrations can damage equipment.

Step 6 – Install piping network Run a clean pipe to the tank discharge opening, bushing up or down as necessary with clean bushings and fittings. Note that the more bushings and fittings placed in the air distribution system, the greater the opportunity for air leaks and breaks. FS Curtis recommends the installation of drip legs in the distribution line. Always install a safety relief valve in the distribution line between the compressor unit and in-line shutoff valves. If more than one compressor pumps into a common system, a check valve in the distribution line of each compressor unit is recommended to prevent moisture from entering the cylinder head(s) when one compressor is idle. A globe or gate valve (WOG rated) installed in the discharge line will allow compressor isolation from plant air system for compressor maintenance. (Note: A safety relief valve should be located between the compressor and the globe/gate valve.)

Step 7 – Install Compressor Intake (IF APPLICABLE) If the compressor intake is to be located away from the unit, please use the following instructions to ensure safe and efficient operation. Run a clean pipe to the compressor suction opening, bushing up or down as necessary with clean bushings and fittings. Note that the more bushings and fittings placed in the intake line, the greater opportunity for air leaks and breaks. If the run is over 10 feet in length, use a larger pipe diameter to avoid excessive pressure drops. When installing the pipes, please pitch the piping down and slightly away from the intake, to ensure that debris and condensation drains away from the compressor.

Post Installation Checklist

WARNING! Failure to perform the post installation checklist may result in mechanical failure, property damage, serious injury or even death.

Steps 1 through 9 should be performed prior to connecting the unit to a power source. If any condition on the checklist is not satisfied, make the necessary adjustments or corrections before starting the compressor.

1. Remove all installation tools from the compressor and check for installation debris. Abrasive dust can seriously damage the air intake and belt assemblies.

2. All FS Curtis compressors are shipped from the factory filled with the required amount of Curtis Lube Plus Compressor Lubricant specially formulated for Curtis Compressors. The oil level should register in the center of the oil sight glass or between the high and low marks on the dipstick. For additional lubricant contact Clark Heintz Tools & Equipment, LLC, authorized distributor. Failure to use authorized lubricant will void the manufacturer’s warranty.

3. Check inlet-piping installation.

4. Check all pressure connections for tightness.

5. Make sure all pressure relief valves in the air distribution are correctly installed.

6. Make sure all guards are in place and securely mounted.

7. Open all manual shutoff valves at and beyond the compressor and tank discharges.

8. Check and tighten all connections (mechanical and electrical) as they may have loosened during shipment. 9. After all the above conditions have been satisfied, the unit can be connected to the proper power source.

Electrical Requirements

TANK MOUNTED UNITS

The electrical installation of this unit should only be performed by a qualified electrician with knowledge of the National Electrical Code (N.E.C.), O.S.H.A. code and/or any local or state codes having precedence. All FS Curtis tank-mounted compressors come with a factory installed, pre-wired starter, if you wish to provide your own starter, please contact your local distributor for more information. Check the electrical supply for voltage, phase, and frequency to see that they match the nameplate stampings on the motor, magnetic starter, solenoids, and other controls. Before attempting to service electrical systems, ensure that maintenance personal are properly qualified, and service procedures comply with NFPA 70-1984, National Electrical Code, National Electrical Safety Code, as well as any applicable state and local regulations. Failure to abide by the national, state and local codes may result in physical harm and/or property damage and will void the manufacturer’s warranty.